The future power grid will be developed in the direction of large capacity, long distance, high economic efficiency, high reliability, and low environmental impact, while the development of distributed energy, offshore wind power delivery, and development of island resources will also rely on DC cables for power transmission.

Therefore, the research and development of high-voltage DC cables is particularly important and will make a big difference.

Compared with the AC transmission system, the DC transmission system has the advantages of large transmission capacity and long transmission distance, etc., and the DC transmission system power regulation is fast and flexible, the risk of widespread chain failures is low, and the system operation is more reliable.

High-voltage DC cable is an important part of the DC transmission system, widely used in wind power grids, island power supply, and cross-sea long-distance power transmission.

Studies have shown that in cable projects with a transmission distance of more than 40km, high-voltage DC cables have a cost advantage, and the longer the distance, the more obvious the advantage.

As one of the key equipment in DC transmission, the safe operation of HVDC cables is crucial for the stability of the HV transmission network.

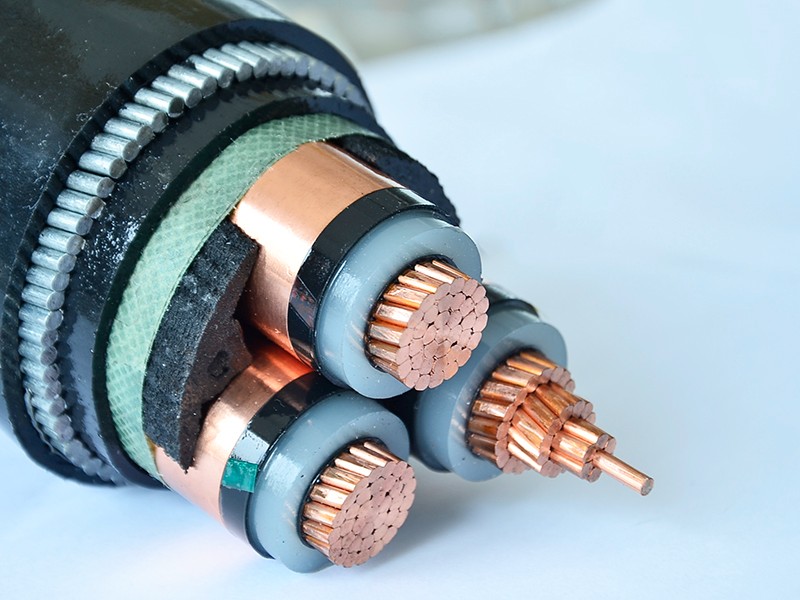

DC cables are divided into winding insulation cables and extruded insulation cables.

Extruded DC cables currently mainly use polyethylene as the insulation medium.

The internal structure of polyethylene cables is strong and simple, easy to produce and install, and has received widespread attention in the recent past.

At present all the indicators of extruded DC cables are better than rubber-impregnated solid cables.

AC cable insulation layer is mainly subjected to industrial frequency AC voltage, its electric field distribution and dielectric coefficient are inversely distributed.

In general, it can be considered that the dielectric constant of the insulating material is almost independent of the temperature, so the electric field distribution in the cable insulation layer and the temperature distribution are almost irrelevant.

DC cable insulation layer is mainly subjected to DC voltage, the electric field distribution and volume resistivity is proportional to the distribution.

As the resistivity of polymer insulation materials is very sensitive to temperature changes, in general, the resistivity with the increase in temperature and an exponential decrease, so in the normal operation of extruded DC cables will appear in the electric field reversal phenomenon, that is the electric field strength of the largest place in the outer surface of the insulation layer.

Secondly, AC cables do not have the problem of space charge accumulation during operation because the polarity of the voltage at both ends of the insulation layer is constantly changing.

On the other hand, DC cables may accumulate space charge during operation because the voltage polarity remains unchanged, and the accumulation of space charge is closely related to the occurrence of faults in DC cables.

The accumulation of space charge in the cable insulation layer will distort the local electric field within the medium, which in turn causes partial discharge and media breakdown, especially in the strong electric field under the action of space charge accumulation, which will accelerate the polymer dielectric's aging process.

Internationally, Europe and Japan have many years of operational experience in extruded DC cables.

Europe is in the leading position in the manufacturing, installation, and R&D of DC cables, with world-famous cable manufacturers ABB (Switzerland), Nexans (France), and Prysmian (Italy), as well as cable material suppliers Nordic Chemical.

Japan has also invested a lot of energy in researching and developing DC cables and achieved good results. Japanese scholars have achieved good results by adding nanoparticles to traditional AC cables to improve their space charge performance.

China's DC cable R & D, production, construction, and operation level has also carried out a lot of work, but compared with the world's advanced level there is still a big gap between the actual engineering applications of most of the power cables are dependent on imports, the domestic production of products are also basically imported cable materials.

The actual commercial application of DC cables in China has just begun.

The main properties of DC cable insulation materials include electrical conductivity, thermal conductivity, mechanical, and space charge characteristics, and environmental friendliness.

How to regulate the various properties of cable insulation materials is a long-term commitment to domestic and foreign scholars to solve the problem.

The development of extruded DC cables needs to solve the two key scientific problems of the generation, transportation, accumulation, and dissipation process of dielectric space charge under the action of multi-field coupling, as well as the synergistic regulation of multiple properties of the insulating medium. The future main research includes:

1. Multi-field coupling under the action of solid insulating medium in the steady state and transient process of space charge generation, transport, accumulation, dissipation of the law of change and its interaction with the conductivity of the process, the polarity reversal of space charge relaxation characteristics, as well as nanoparticles and nanofibers of inorganic on the space charge injection and inhibition of the law of the influence of the aging characteristics of the insulation and the characteristics of the impact.

2. The regulation mechanism and regulation method of nanocomposites on space charge, internal electric field, and heat field distribution.

Research nanoparticle interface structure design to change the nanoparticle physicochemical environment, such as particle surface chemical functional groups, nanoparticles, and polymer matrix to change the interaction of nanoparticles, nanoparticles of the physicochemical environment of the composite insulating medium on the internal electric field distribution and thermal field distribution of the modulation of the role of nanoparticle physical-chemical environment; solid insulating medium in the nano-dimensional array structure of the medium of the electric field and the thermal field of the influence of the law.

As well as the coordinated control of the physical-chemical laws and methods of multi-performance regulation. Physical and chemical laws and methods.

3. The generation, development, and evolution of defects in the insulation system within DC cables, as well as the characterization parameters of insulation aging and defective states.

The influence of nano-doping on the long-term operating characteristics of extruded DC cables is obtained through the study.

4. Establishing a green and environmentally friendly matrix material system for high-voltage DC cable insulation, realizing the synergistic and optimal regulation of the electric and thermal fields of the new insulating matrix material under high-voltage DC through the addition of nano-inorganic particles, and solving the basic problems of producing extruded super- and extra-high-voltage DC plastic cables.