Cable heating problem has been industrial enterprises or civil building equipment operation process plagued the operation and maintenance personnel.

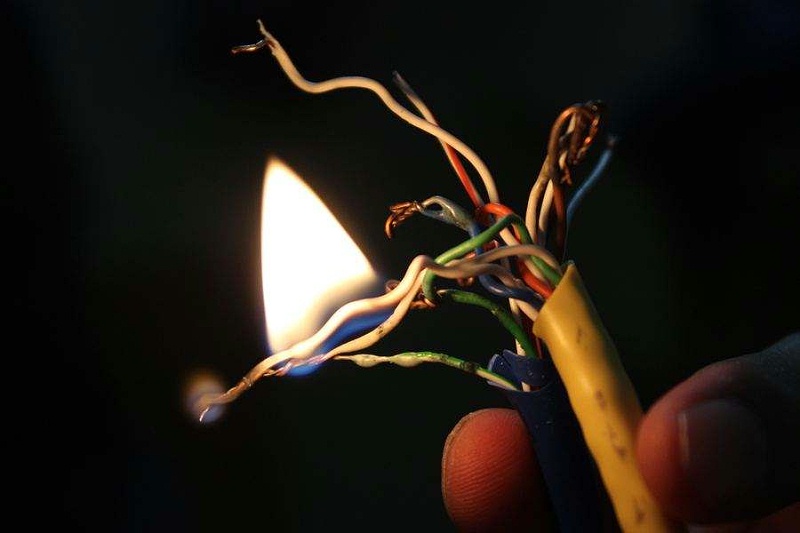

Solving the problem of long-term cable heating is bound to accelerate the cable and equipment insulation aging, and even lead to insulation breakdown fire!

How to solve the heating problem of the cable? Many people will not pay attention to this problem, and think cable heating is normal natural consumption.

ZMS cable editor as a cable industry professional, first takes you to understand what serious harm can be caused by cable heating.

Cable heating phenomenon, If you do not find the cause of timely troubleshooting, the cable continues to run continuously energized will produce a thermal breakdown of insulation.

Caused by the cable phase short circuit tripping phenomenon, may cause a serious fire.

The following content analyzes the causes of cable heating and puts forward reasonable measures to solve the problem.

Cables are the medium for power system power transmission.

Essentially, the cable is also an electrical load, only because the cable's own resistance is very small.

Under normal circumstances in the cable loss of electricity accounted for a small proportion of the total transmission and distribution of energy.

The following factors cause the cable to heat up abnormally:

The cable is not produced in accordance with national standards for standard cross-section, resulting in the cable itself resistance exceeding the standard.

The copper used for cables contains too many impurities and does not meet the purity standard of electrical copper, resulting in the cable itself resistance exceeding the standard.

The thickness of the cable insulation layer does not meet the standard or the amount of glue in the insulation material does not meet the standard, resulting in the insulation resistance of the cable between the phases does not meet the standard.

Cable selection and load current mismatch, long-term more than the normal operation of the cable current-carrying capacity.

During construction, the terminal size is small or the terminal is not tightly crimped with the cable, resulting in the resistance at the cable end exceeding the standard.

Cable laying is too dense, resulting in the normal operation of the cable heat is not dissipated in time.

Cable laying in the slot box or closed bridge, is not conducive to heat dissipation.

Cables are laid around heat sources, e.g. near heat pipes, and are not insulated.

Ordinary cables are used for high-frequency loads, resulting in overheating of the cables.

Excessive harmonic content in the grid, which does not match the cable design, leads to overloading.

1 Strictly according to the standard parameters to provide test reports

Including cross-sectional area, copper content, insulation thickness, and insulation materials such as rubber content and other indicators.

2 Strictly control the design and selection

In accordance with national standards, the cable selection principle is: that the cable current-carrying capacity should be greater than the rated current rectification value of the circuit breaker at this level.

In the project, it is wrong to use the load calculation current as the basis for selecting the cable current-carrying capacity.

3 Strictly in accordance with the operation of the test

Before the cable installation, the insulation resistance of the cable is detected in strict accordance with the operating procedures.

Terminals meet the requirements of the standard cross-section, crimping construction standard specifications, in line with the requirements of the construction process.

Cable laying to avoid disorganization, stacking too dense, and other irregularities.

Fixed in accordance with the specification requirements, try to avoid multi-layer stacking, which should be laid in a single layer, up to two layers.

For cables laid in the slot box or airtight bridge, properly set up ventilation holes, or take the necessary ventilation measures.

When cables are laid in close proximity to the heat source, the spacing distance required by the specification is complied with, or measures such as heat-insulating boards are taken.

High-frequency loads should use high-frequency special cables.

Harmonic management measures of the power grid are not limited to the centralized management of the substation, but also according to the site conditions appropriate increase in situ compensation.