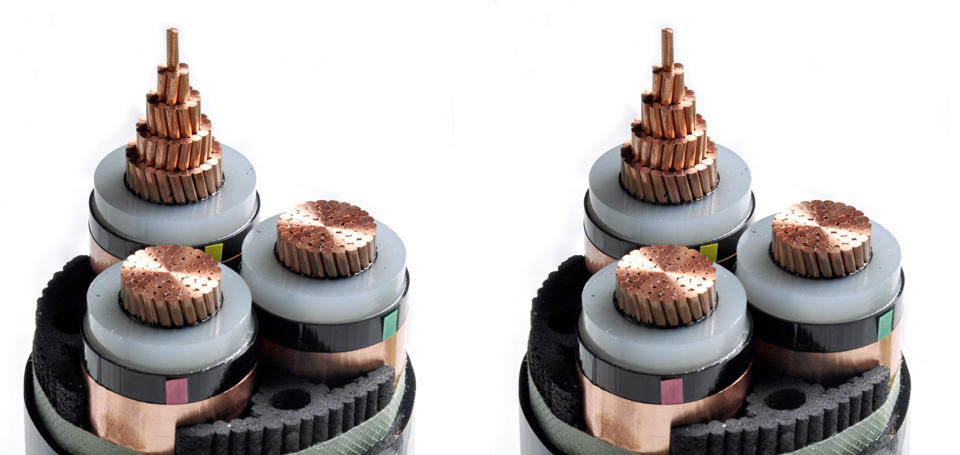

Crosslinked cables usually refer to the use of cross-linked materials for the insulation of the cable. The most commonly used materials are cross-linked polyethylene (XLPE).

The cross-linking process is the use of linear molecular structure of polyethylene (PE) material through a specific processing methods, so that the formation of mesh-type sub-structured cross-linked polyethylene. (Or higher), and the short circuit allows the temperature to increase from 140℃ to 250℃ (or higher), greatly improving the overall electrical performance Actual use performance.

At present, the cable industry produces cross-linked cable technology is divided into three categories: the first type of peroxide chemical cross-linking, including saturated vapor cross.

Inert gas cross-linking, molten salt crosslinking, silicone oil cross-linking, the domestic are the second type of dry chemical cross-linking; the second type of silane chemical cross-linking; the third category of radiation cross-linking.

The crosslinking process of the conductor shield insulating layer was completed by the three-layer coextrusion by the addition of the peroxide insulating material of the peroxide crosslinking agent, and the crosslinking process was completed continuously and uniformly through the sealed cross-linking tube filled with high temperature and high pressure nitrogen.

Heat transfer medium for the nitrogen, cross-linked polyethylene electrical performance, production range up to 500KV class.

Using the addition of silane cross-linking agent of polyethylene insulation material, through the 1 +2 extrusion method to complete the extrusion of allogeneic insulation shield, the cooling plate has been insulated wire core immersed in 85-95℃ hot water for hydrolysis The wet cross-linking affects the moisture content in the insulation. Generally the highest voltage level is only 10KV.

Using the modified polyethylene insulation material, through the 1 +2 extrusion method to complete the all-dimensional shielding layer - insulation - insulation shield extrusion, the cooling of the insulation core, even through the high-energy electronic accelerator Irradiation scan window to complete the crosslinking process.

However, due to the energy level of the accelerator limit (generally not more than 3.0Mev electron beam effective penetration thickness of 10mm or less), taking into account the geometric factor, the production of the cable voltage level can only reach 10KV, the advantages of 6KV below.

At present in the cable production, the most commonly used insulating plastic polyethylene and polyvinyl chloride, polyethylene materials which have better electrical properties and good cross-linking, and thus the development of a variety of industrial cross-linked production technology, Cross - linking and cross - linking.

In addition to the performance of the table below, in the production and laying process, the current commonly used cross-linked cable insulation layer showed a greater hardness and strength, especially more than PVC insulation stripping increased difficulty. As the cross-linking performance of the cross-linked cable is the best, the highest degree of cross-linking, the relative peel strength is also the largest. If the cross-linking of the cross-linked cable insulation is easier , it must be that the cross-linking is not enough or is not cross-linked.

Under normal circumstances, the cross-linking cable produced by the cross-linking process of warm water, there is more than the degree of cross-linking more, because the original cross-linking of such products is relatively low, and cross-linking process is not continuous, can not be automatically controlled Human factors are very influential and prone to cross-linking.