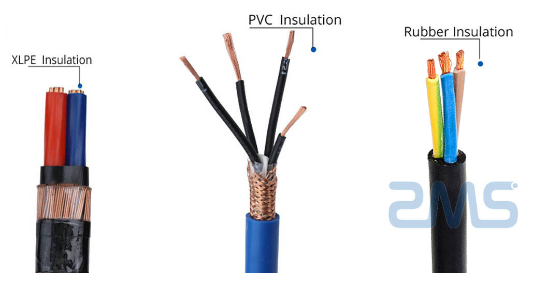

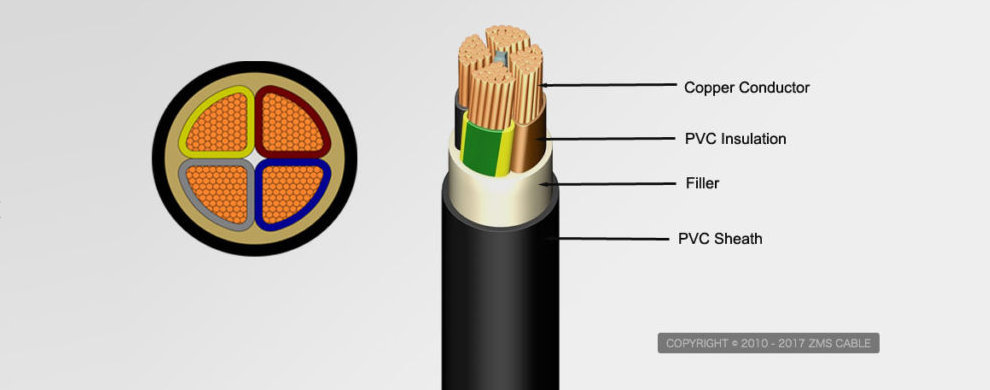

The cross-linked cable is referred to as a cross-linked polyethylene insulated cable. Cross-linked cable for the frequency AC voltage 500KV and below the transmission and distribution lines.

At present, most of the high-voltage cables are used cross-linked polyethylene insulation.

Crosslinked cables usually refer to the use of cross-linked materials for the insulation of the cable. The most commonly used materials are cross-linked polyethylene (XLPE).

The cross-linking process is the use of linear molecular structure of polyethylene (PE) material through a specific processing methods, so that the formation of mesh-type sub-structured cross-linked polyethylene.

So that the long-term allowable operating temperature from 70 ℃ to 90 ℃ (or higher), short circuit allows the temperature from 140 ℃ to 250 ℃ (or higher), to maintain its original excellent electrical performance under the premise of greatly improved Actual use performance.

At present, the cable industry produces cross-linked cable technology is divided into three categories:

1. peroxide chemical cross-linking, including saturated steam crosslinking, inert gas cross-linking, molten salt crosslinking, silicone oil cross-linking, the domestic use of the second is dry chemical cross-linking;

2. silane chemical crosslinking;

3. irradiation cross-linking.

At present, the use of polyethylene cable with cross-linked functional particles, ordinary polyethylene cable material can be added to a small amount of the function of the mother particles, the extruded cable can be cross-linked cable.

Cable cross-linking function of the mother particles are divided into three types: chemical cross-linking function, electron beam irradiation cross-linking function, ultraviolet radiation cross-linking function.

1. chemical crosslinking cable with cross-linking function of the mother particles, model: DH-125Y.

DH-125Y chemical cross-linking function of the mother particles for the appearance of colorless LLDPE plastic particles. Wire and cable factory only need to purchase the market common LLDPE polyethylene ordinary plastic particles, such as LLDPE7042 and so on.

In the 25 kg LLDPE7042 plastic particles by adding 1 kg of DH-125Y functional mother particles, with manual flip evenly, directly into the cable cable extruder, extrusion cable, that is made of cross-linked wire and cable. The function of the mother particles can produce 35KV and below the cross-linked wire and cable.

2. electron beam irradiation cross-linked cable with cross-linked functional particles, model: DH-125DF

DH-125DF electron beam irradiation cross-linking function of the mother particle appearance of colorless LLDPE plastic particles. 7042 plastic particles by adding 1 kg of DH-125DF functional mother particles, hand flip evenly, directly into the cable cable extruder, extrusion cable, the electron beam irradiation that is made of cross-linked wire and cable. The function of the mother particles can produce long-term working temperature at 125 ℃ cross-linked wire and cable.

3. UV irradiation cross-linked cable with cross-linked functional particles, model: DH-125ZF.

DH-125ZF UV irradiation cross-linking function of the mother particles for the appearance of colorless LLDPE plastic particles. 7042 plastic particles by adding 1 kg of DH-125ZF functional mother particles, hand flip evenly, directly into the cable cable extruder, extrusion cable, by ultraviolet light that is made of cross-linked wire and cable.

The function of the mother particles can produce long-term working environment temperature at 125 ℃ cross-linked wire and cable.

1. save money

Reduce the cost of cable manufacturers directly use, than the market procurement of chemical, radiation cross-linked polyethylene cable special material prices cheaper 1500 ~ 3000 yuan / ton.

2. save time

Cable production plant procurement of chemical, radiation cross-linked polyethylene cable special materials need to inquiry, order, production, transportation of the week or so of the time period. With DH-125 functional mother particles, in the decision after the production plan, 5 minutes to prepare can be directly cable production.