When the power cable passes a certain load current, it will definitely heat up.

As the load current increases, the temperature of the cable surface will be higher.

If it is not processed in time, the consequences can be imagined.

For example, a polyvinyl chloride (PVC) cable is considered to have a core temperature of 70 degrees as the upper limit, and the surface temperature is 5 to 10 degrees lower.

Therefore, the cable surface temperature is basically safe below 60 degrees.

From the viewpoint of power supply maintenance, of course, the lower the temperature, the better.

The reasons for the heating of the cable during operation are as follows:

1. The cable conductor resistance does not meet the requirements, causing the cable to generate heat during operation.

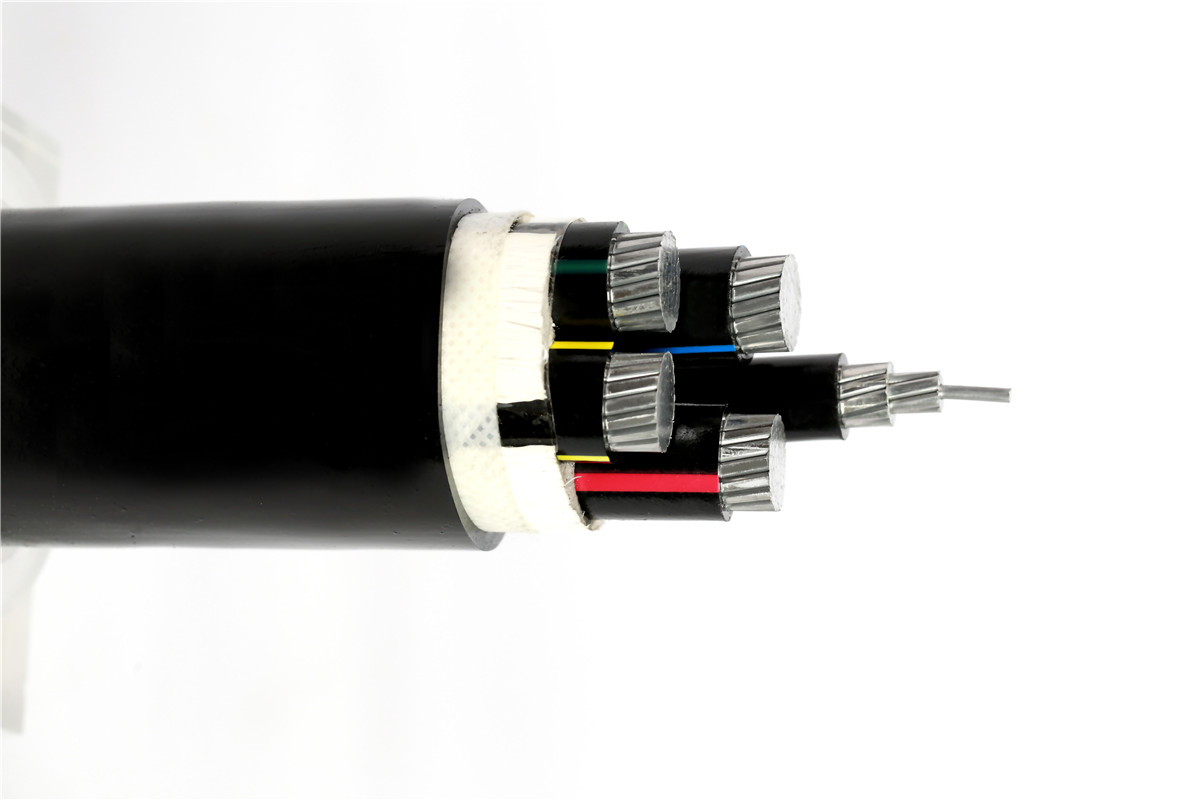

2. The cable selection type is improper, causing the conductor cross-section of the cable to be used to be too small, and an overload phenomenon occurs during operation.

After a long time of use, the heat generation and heat dissipation of the cable is unbalanced causing heat generation.

3. When the cable is installed, the arrangement is too dense, the ventilation and heat dissipation effect is not good, or the cable is too close to other heat sources, which affects the normal heat dissipation of the cable, and may also cause the cable to generate heat during operation.

4. The joint manufacturing technology is not good, the crimping is not tight, and the contact resistance at the joint is too large, which may cause the cable to generate heat.

5. The cable phase insulation performance is not good, resulting in less insulation resistance, heating will also occur during operation.

6. The partial sheath of the armored cable is damaged.

After the water enters, the insulation performance will be slowly destructive, resulting in a gradual decrease in the insulation resistance, which will also cause heating in the cable operation.

After the cable is heated, if the fault is not found, the insulation will break down after continuous energization.

This causes the cable to phase-to-phase short-circuit trip, which may cause a fire.

The power cord can be seen everywhere in family life, the electrical appliances are basically inseparable from the power cord, so this small power cord may despise him.

The heater plug of the water heater is usually caused by poor cooperation with the socket.

At the same time, it is necessary to take into account the normal heating phenomenon.

If the surface temperature of the plug is less than the ambient temperature plus 50 degrees Celsius, it is normal.

If you have abnormal heat, you need to consider replacing the socket or checking the plug and socket.

1. Poor contact between the plug and the socket, plus the high load power, causes the plug to heat up. Such as electric kettles, electric irons, etc.

2. The inside of the new plug is loose, which is caused by the rough production process.

3. The old plug is used for a long time, and the insulation performance is degraded (or the plug is loose).

4. The water valve is not closed, causing the socket to come into contact with water.