High-temperature wire and cable are required in aerospace, rolling stock, energy, steel, non-ferrous metal smelting, oil extraction, electrical machinery, construction, and other fields.

The long-term continuous working temperature of 125 °, 135 °, 150 °, 180 °, 200 °, 250 °, and 250 ° high-temperature wire and cable, commonly used radiation cross-linked polyolefin, silicone rubber, fluoro resin, polyamide Wire, and lines such as amine, mica, and magnesium oxide.

Now introduced; two new high-temperature wires and cable.

It has excellent heat resistance, physical and mechanical properties, electrical insulation properties, extrusion molding properties, and especially has the outstanding advantages of being able to maintain stable performance in an environment where continuous use at high temperatures and rapid temperature changes:

Heat distortion temperature is 200 -220 degrees, continuous use temperature is 180-200 degrees, UL temperature index is 180 degrees.

Can withstand 150-160 degrees hot water or steam, free from acid and alkali corrosion at high temperatures.

Elastic modulus at -100-- 200 degrees is almost unchanged, especially above 100 degrees, better than any thermoplastic resin.

The coefficient of linear expansion is small, and its temperature dependence is small.

It is non-toxic, recognized by the US FDA, and also conforms to No. 434 of the Ministry of Health and Welfare of Japan.

The requirements of Announcement No. 178.

Self-extinguishing, without adding any flame retardant, has excellent flame retardancy, up to UL94V-0 (0.46mm).

Polyetheretherketone is a super heat-resistant thermoplastic resin. The long-term continuous use temperature is 250 degrees and the UL temperature index is 250 degrees.

PEEK is a flexible resin with good creep resistance.

It is self-extinguishing and can be UL94V-1 (thickness 0.3mm), 94V-0 (thickness 1.5mm), and 94V-5 (thickness 3.2mm) without any flame retardant.

Special Structure

1. Low Inductance Cable

There are strong and weak electricity points. Here is a low-inductance cable for solid electricity.

This cable is equipped with a heat-dissipating device, which connects various contact welding machines, electric arc welding machines, and pneumatic welding tongs.

It has a simple and reasonable structure, large cooling water circulation, and no blockage. Blocking and current limiting phenomena, good heat dissipation, and long service life.

The new low-sensitivity cable also includes connectors that are fixed on the cable and cable ends, and the cable is also composed of a positive core and a negative core in the outer hose.

Since such low-inductance cables are generally used for voltages of 25-50V and currents between 7000-12000A, the short-circuit conduction phenomenon of cooling water in the cable is basically negligible, so there is no such low-inductance cable.

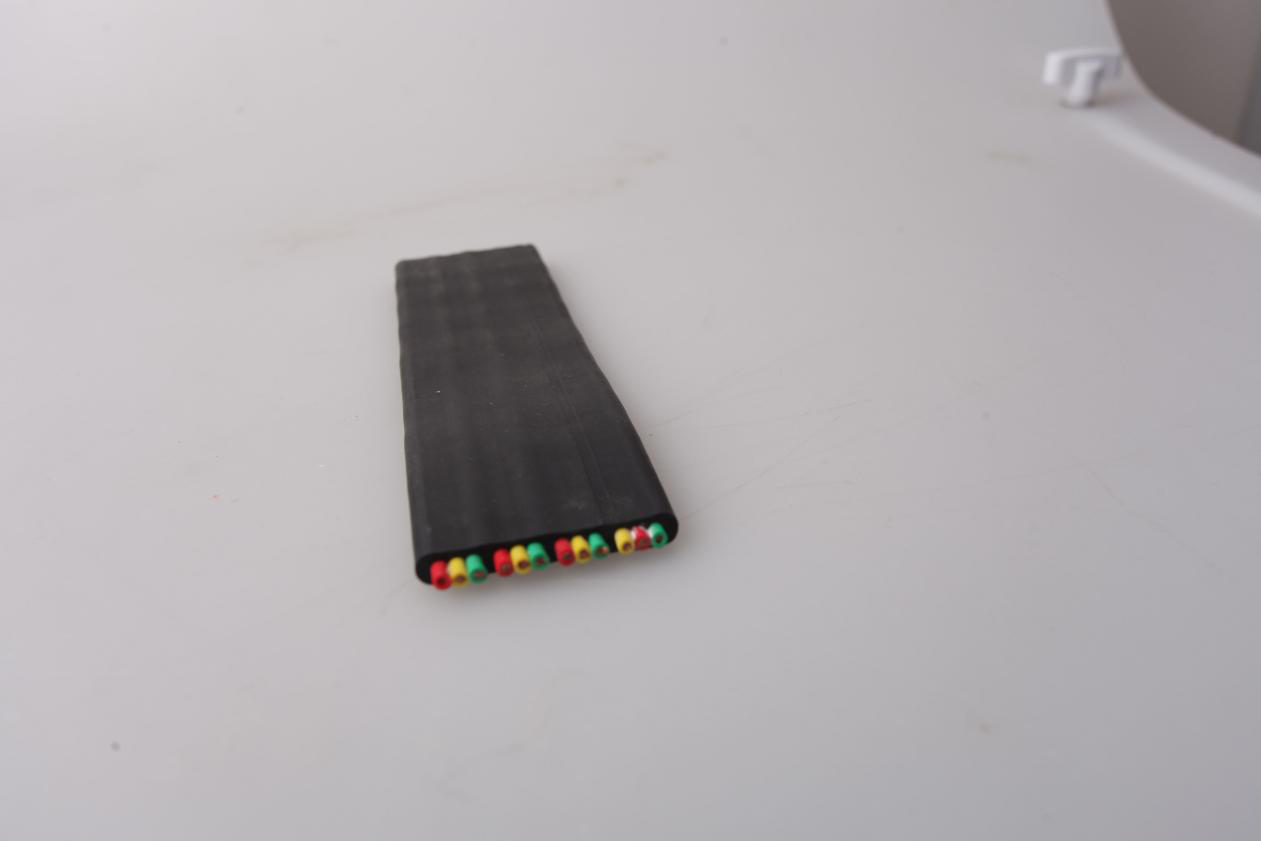

The rubber hose that isolates the positive and negative cores is specially provided with a core frame with a cross-section in the shape of a spoke (commonly known as "plum core"), surrounded by the "round center" and the adjacent "spokes".

The space formed in the direction of the axis includes a longitudinal groove, and the longitudinal groove on the core frame is the same as the total number of the positive cores disposed on the cable, and the cable portion is placed on the positive and negative cores respectively.

The longitudinally grooved device of the core frame is constructed in an outer hose.

The heads of the positive and negative cores are clamped into the core clamp and then fixed on the joint. The end of the outer hose of the cable is set at the end of the joint and used.

The tightening of the tightening outside outer hose is tightly sealed.

2. Low-Noise Cable

Under external factors such as bending, vibration, shock, temperature change, etc., the cable with a pulse signal less than 5mV generated by the cable itself is called a low-noise cable, also called a shock-proof instrument cable.

They were used to measure small signals in many fields such as industry, medicine, and defense.

There are various types of cables, such as polyethylene insulated low noise cable, F46 insulated low noise cable, radiation resistant low noise cable, low capacitance low noise cable, hydrophone cable, and watertight low noise cable.

The causes of noise in the cable are:

1) Internal molecular friction of the medium itself.

2) Change in cable capacitance.

3) Piezoelectric effect of the cable medium.

4) Friction between the conductor and the medium in the cable to generate a charge, ie between the conductor and the insulation Separation of charge occurs when contact is broken.

A low-noise cable with a thin semi-conducting (thickness of 0.20-0.30mm) on the polyethylene insulation.