General tests are similar for all the cables.

Let the comparison is made between the cables in the High Voltage test, which is the Type, Routine, and Acceptance test. On the XLPE cables.

High Voltage Test at Room Temperature is performed by testing the cables to withstand a voltage of 3 kV ac (RMS) at a frequency of 40 to 60 Hz or an ac voltage of 7.2 kV, between conductors and between conductors and ECC (if any) for a period of 5 minutes for each test connection.

On the PVC cables, a High Voltage Test at Room Temperature is performed by testing the cable to withstand an a.c. the voltage of 3 kV( RMS ) or a dc voltage of 7.2 kV.

The duration of the test shall be 5 minutes for each connection.

The core or cores ( not exceeding five cores in the case of multicore cables ) shall be carefully removed from a sample approximately 3 m long taken from the finished cable.

They shall be so immersed in a water bath that their ends protrude at least 200 mm above the water level.

The temperature of the water bath shall be 6O?C for cores with general-purpose PVC insulation and 70?C for cores with heat-resisting PVC insulation.

After 24 hours, a voltage of 3 kV ( RMS ) shall be applied between the conductors and water.

This voltage shall be raised to 6 kV ( RMS ) within 10 seconds and held constant at this value for 5 minutes.

If the sample fails in this test, one more sample shall be subjected to this test. There shall be no failure in the repeat test.

And d.c. Test; the cores which have passed the preliminary test in the a.c test shall be subsequently tested with a d.c. the voltage of 1.2 kV in the same water bath at the same temperature.

The core shall withstand this voltage for 240 hours without breakdown.

The High Voltage Test is performed as a Type/Acceptance Test and Routine Test.

The Type test for 1.1 kV grade cables is carried out by removing the power/pilot core(s) from a sample approximately 3 meters long, taken from the finished cable.

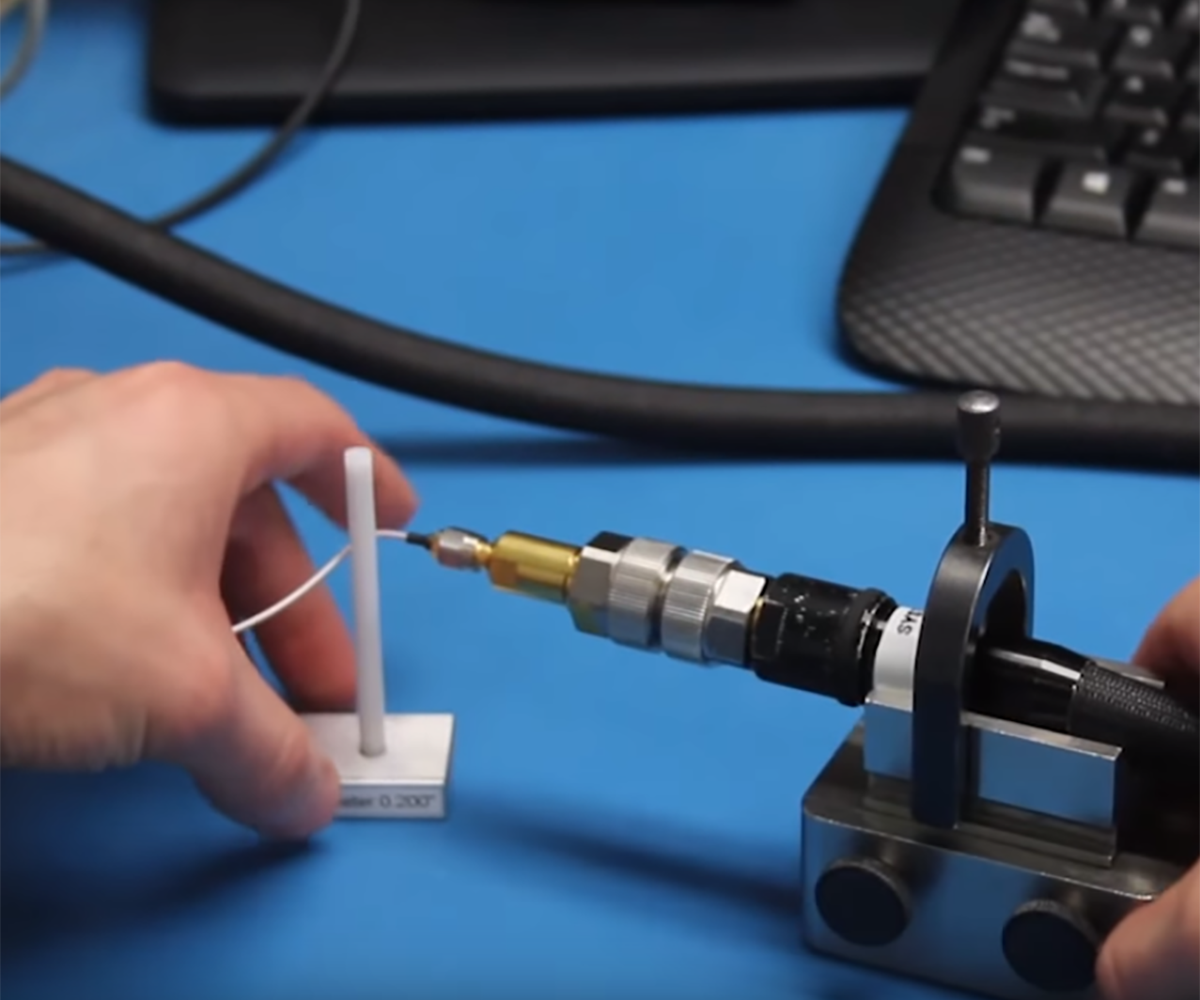

They shall be so immersed in a water bath at room temperature that their ends protrude at least 200 mm above the water level.

After 24 hours, an ac voltage of 3 kV (RMS) shall be applied between the conductor and water.

This voltage shall be raised to 6 kV (RMS) within 10 seconds and held constant at this value for 5 minutes. If the sample fails in this test, one more sample shall be subjected to this test which shall pass.

For 3.3 kV and above grade cables the type /acceptance tests shall be four hours test.

The cables shall withstand without breakdown, an ac voltage equal to 3U when applied to the sample between conductor and screen/armor (and between conductors in case of unscreened cables).

The voltage shall be gradually increased to the specified value and maintained for four hours.

This test is applicable to power cores only. The Routine test is performed by testing the cable to withstand, without breakdown a power frequency ac voltage as specified below in the table.

The voltage shall be applied and increased gradually to the full value and maintained for five minutes. The test shall be carried out at room temperature.