With the widespread dissemination of wire and cable, people are increasingly aware of its related knowledge.

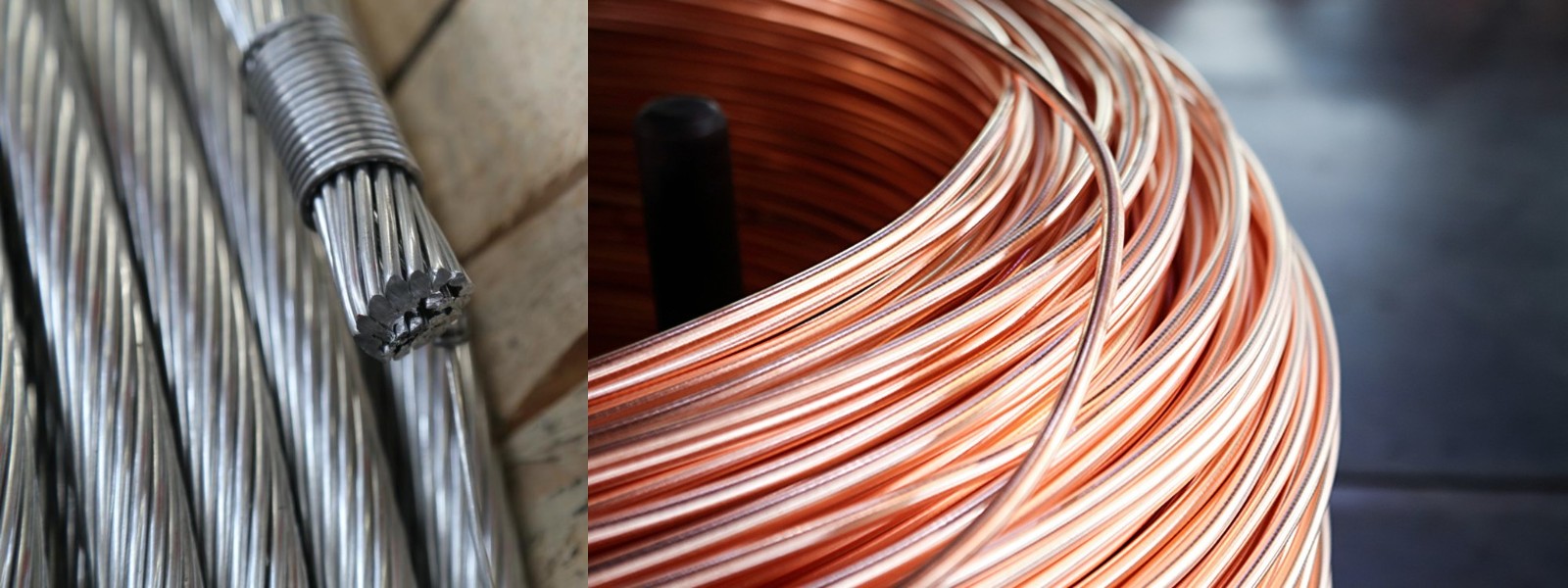

We all know that copper and aluminum is the main material of wire and cable, and so do copper-core cable and aluminum-core cable that has more advantages. The following ZMS cable takes you to understand the advantages of copper-core cable over aluminum-core cable what are?

As the resistance of the aluminum-core cable is about 1.68 times higher than the resistance of the copper-core cable, the resistivity of copper-core cable is relatively low, the same cross-section of copper-core cable than aluminum-core cable, the current-carrying capacity of the copper-core cable is generally higher than that of aluminum-core cable.

Metals have good ductilities, such as gold, platinum, copper, silver, tungsten, and aluminum are rich in ductility, of which the ductility of copper alloy is 20 ~ 40% and the ductility of copper for electricians is more than 30%.

Copper wire and cable repeatedly bent by hand is not easy to break, good fatigue strength, aluminum is very easy to break, in terms of elasticity index, copper than aluminum is about 1.7 ~ 1.8 times higher.

Aluminum-core cable joints are unstable and will react with air oxidation, resulting in increased resistance of the cable conductor, causing the conductor to heat up and accidents.

The joints of copper-core cables are more stable and will not cause accidents due to oxidation, so the stability of copper-core cables is much higher than that of aluminum-core cables.

Due to the lower resistivity of copper-core cables, the voltage drop of copper-core cables is small in the case of the same current flowing through the same cross-section.

At the same transmission distance, copper-core cables can ensure higher voltage quality.

Under the condition of allowed voltage drop, copper-core cable transmission can reach a longer distance, i.e., the power supply covers a larger area, which is conducive to the planning of the network and reduces the number of power supply points set.

Aluminum-core cables have greater resistance, and their performance in all aspects is much lower than that of copper-core cables.

Because the elasticity of copper-core cable is much higher than aluminum-core cable, repeated bending is not easy to break, better flexibility, allowing a smaller radius of bending, so it is easier to turn during the laying process, and more convenient to wear the tube, in addition, the high mechanical strength of the copper-core cable, can withstand greater external damage, providing greater convenience in the construction process.

From the above situation, copper core cable has low resistivity, good ductility, good elasticity, good oxygen resistance, high load capacity, and other advantageous properties in the cable power supply, has outstanding advantages.

ZMS cable manufacturer consistently uses high-purity oxygen-free copper as the core to eliminate the occurrence of overload, while the use of self-developed environmentally friendly materials as insulation, greatly reduces the risk of leakage and short circuit.

As the ground line to use more by your family to bring multiple protection, so in line with the national standard of cable to truly protect our lives.

The above is ZMS cable to provide you with the copper-core cable and aluminum-core cable-related knowledge, I hope it will help you.