With the widespread use of computer technology, the number of control cables is increasing.

For example, two sets of units with more than 300 MW have nearly 1,000 km of control cables, more than 20,000, and 200,000-300,000 cores.

If the control cable head is not beautifully produced, the secondary wiring is confusing and the errors are many, which will seriously affect the quality and progress of the entire project.

Therefore, it is important to improve the manufacturing process of the control cable head and the quality of the secondary wiring.

For the manufacture and secondary wiring of the control cable head, it is necessary to establish a unified standard, and before the construction, all the personnel who participate in the secondary wiring should be technically trained, and then qualified to be employed, and the experienced master will carry out the work. Pass, help, and bring, in order to receive good results. The following conditions should be met before installation.

(1) The materials for making the cable head and the materials for the second wiring are ready.

(2) The buttons, cabinets, and boxes on the ground that have been connected by the cable have been installed and accepted.

(3) The cable laid has been confirmed, and the finishing and fixing are completed.

(4) The secondary wiring drawing has been confirmed to be correct.

(5) Cable insulation has been tested and qualified.

(6) The construction personnel have been trained in the cable head manufacturing method and the secondary wiring process and technical disclosure.

(1) Schematic Diagram

Indicates the working principle and interaction of each circuit. The figure shows not only the connection of the components in the secondary circuit but also the connection related to the primary circuit.

(2) Expand The Map

It is a practical form of the schematic diagram, which is the basis for drawing the installation wiring diagram and the most important drawing in the secondary wiring diagram.

(3) Terminal Block Diagram

A drawing indicating the connection between the on-screen line and the off-screen line.

The manufacturer arranges the terminals according to the terminal block diagram and arranges the secondary wires in the screen. At the construction site, the cables led by other devices are connected to the terminals in the screen.

(4) Install The Wiring Diagram

The actual reflection of the schematic and the expanded view show the actual wiring of the electrical and instrumentation.

The manufacturer shall arrange the secondary wires and the assembled terminal blocks in the screen according to the installation wiring diagram.

This drawing is used as the basis for checking the secondary wiring at the construction site.

(5) Cable Inventory

According to the schematic diagram, the cables for each electrical component are listed, including the cable number, the starting and ending point position, the cable specification model, the cable length, etc., which are the basis for laying the cable.

The secondary wiring construction is closely related to the above drawings. Only when these drawings are understood and made can the wiring work be carried out smoothly.

The procedure for controlling the cable terminal head making and secondary wiring is: familiar with the drawings and technical submissions.

Sort the cables under the disk, the disk, or the equipment. Determine the longest position of the cable core wire and cut the cable.

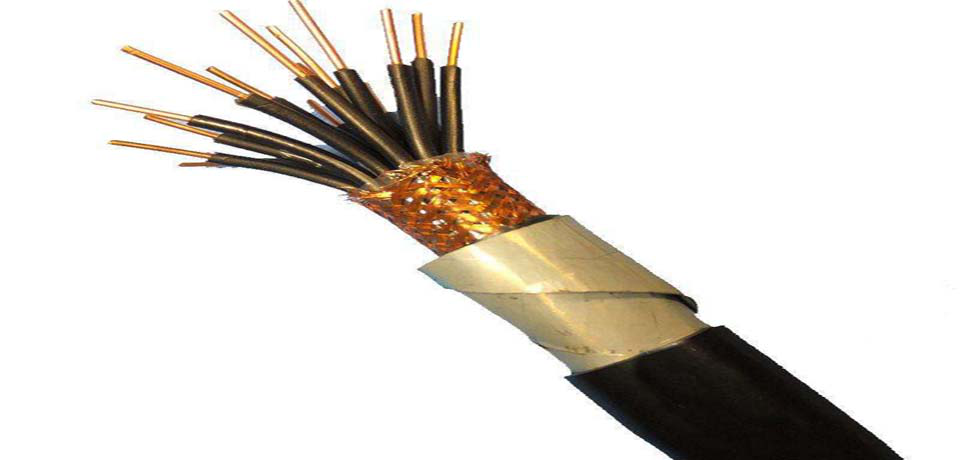

The cable head is made and tagged.

Straightening cable core - cable core line check and split line one line handle, finishing fixed line core one line core set circuit rubber head number one wiring, coordination, debugging, line checking, line change.

The construction personnel should carefully read and familiarize themselves with the secondary line symbol. Check the secondary wiring diagram and the schematic diagram to ensure that the wiring diagram is correct.

The requirements for secondary wiring construction are as follows:

Construction according to the figure, the wiring is correct;

Bolts, plugs, welding, or crimping between the wires and the electrical components should be firm and reliable, with good contact;

The wiring is neat and clean, beautiful;

Good insulation, and no damage;

The wires inside the panel should not have connectors;

The circuit number is correct, the writing is clear, and it is not easy to fall off.

The number of control cable cores is generally large. In order to ensure correct wiring, there should be many methods for correcting the number of cable cores before wiring.

The construction site generally uses a dry battery to line lamps (passing lights) to find the corresponding core from both ends of the cable.

After the control cable is made in the terminal, it should be arranged in 1 or 2 layers according to the number of cables.

It should be arranged horizontally or stepwise and fixed with straps. Generally, the cables connected to the terminal strips at the high end are placed at the rear of the disc.

The cables that are connected to the lower terminal block are sequentially arranged toward the disk side.