Control cable is a kind of cable used in public places.

Especially in daily life commercial buildings are very good applications.

Because of the dense flow of people in commercial buildings, special attention should be paid to the prevention of fire. With the rapid development of the economy, people have put forward higher requirements for the selection and application of control cables.

How to choose the corresponding control cable, first of all, consider the difference in the use of temperature, followed by the environmental protection point of view and the price point of view.

In daily life, control cables have a pivotal role in the electrical industry.

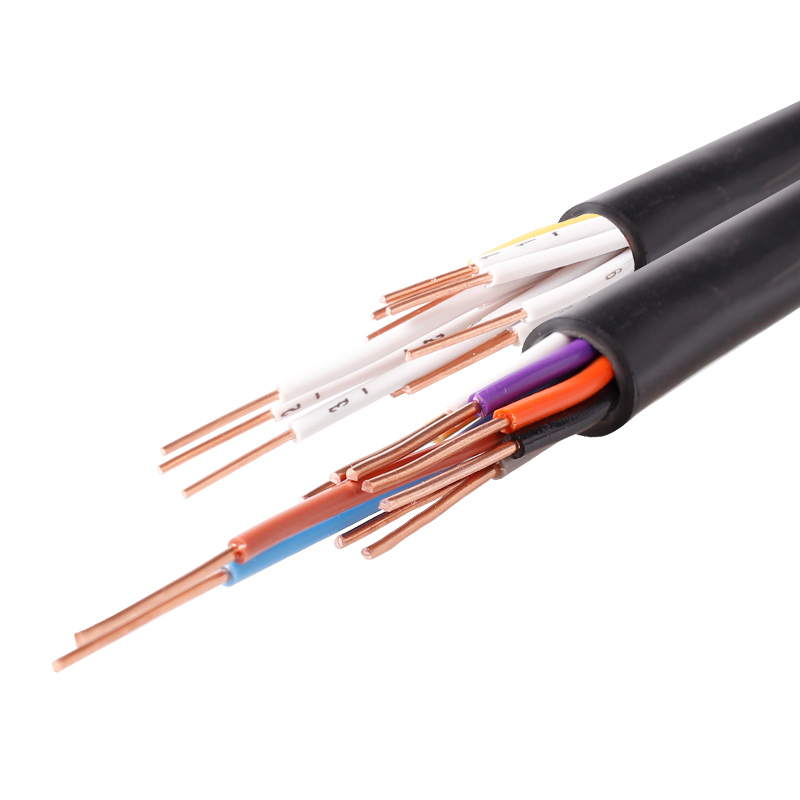

Control series of cables are mostly used in control system lines, according to the different places used, the structure of the cable, materials, and models are different.

The following ZMS cable editorial is for you to introduce how to use the control cable correctly. What are the characteristics?

1 Nowadays, our living standard has been greatly improved, so various commercial buildings have appeared in our life.

Because of the large area of commercial buildings, complex building structure, and many electrical lighting equipments.

The crowd is dense, so the prevention of fire in commercial buildings should pay special attention.

But with the emergence of electrification of life, we do not need to talk about it.

2 In general, some accidents with electricity can be avoided to a considerable extent.

In the cable purchase consider the building's electrical materials basically with copper cable mainly but also a small amount of aluminum alloy cable application, so to make a transition connection with copper cable.

3 The process of installation, there may also be certain hidden dangers.

Coupled with the expansion of copper and aluminum metal, different factors lead to copper cable joints very easy to catch fire, the processing of cable joints needs to be carried out in the field.

4 As there are individual operators who generally lack the standard skills of cable installation.

So in the case of strict operating specifications, aluminum alloy cables are far less reliable than copper cables.

We must be cautious and reasonable in choosing construction and electric infrastructure materials when we purchase control cables so that we can reduce the occurrence of accidents to a large extent.

1 Control cable is suitable for industrial and mining enterprises, energy and transportation sectors, for control of AC rated voltage below 450/750 volts.

Proximity and protection of the line and other occasions to use polyvinyl chloride insulation, and polyvinyl chloride sheathed control cable.

2 Control cables with high fire resistance, within a certain period of time, withstand direct flame combustion will not occur short circuit and short circuit failure.

3 Suitable for a variety of fire hazards, fire safety is more important occasions, as electrical equipment and control systems between the connection line used.

4 Control cable is heated with low smoke emission and does not contain halogen thermoplastic or thermosetting composition.

It is suitable for use as a control connection line in densely populated, low-air-density situations.

The purpose of adding an armor layer to the cable is to enhance the mechanical strength.

For example, tensile strength and compressive strength prolong the service life and improve the anti-interference performance of the cable by shielding protection.

Commonly used armored materials include steel tape, steel wire, aluminum tape, aluminum tubes, and so on. Among them, steel tape and steel wire armor layers have high permeability and good magnetic shielding effect.

It can be used to resist low-frequency interference, and the cable can be buried directly without going through the pipe, which is cheap and practical.

An armored cable mechanical protection layer can be added to any structure of the cable to increase the mechanical strength of the cable and improve corrosion resistance.

This is a special cable designed for use in areas susceptible to mechanical damage and corrosion.

It can be laid in any manner and is more suitable for direct burial in rocky areas.

The more popular armored cable is also buried and cable, power line transmission power cable with an armored layer is designed to enhance tensile strength, compressive strength, and other mechanical protection for longer life.