In the realm of electrical and communication systems, the type of cable used can significantly impact performance, safety, and reliability. One such crucial type is concentric cable.

This comprehensive guide will delve into what concentric cable is, its various models, and its myriad applications.

Whether you’re an engineer, an installer, or simply a curious reader, this article ZMS Cable aims to provide a thorough understanding of concentric cables and their significance.

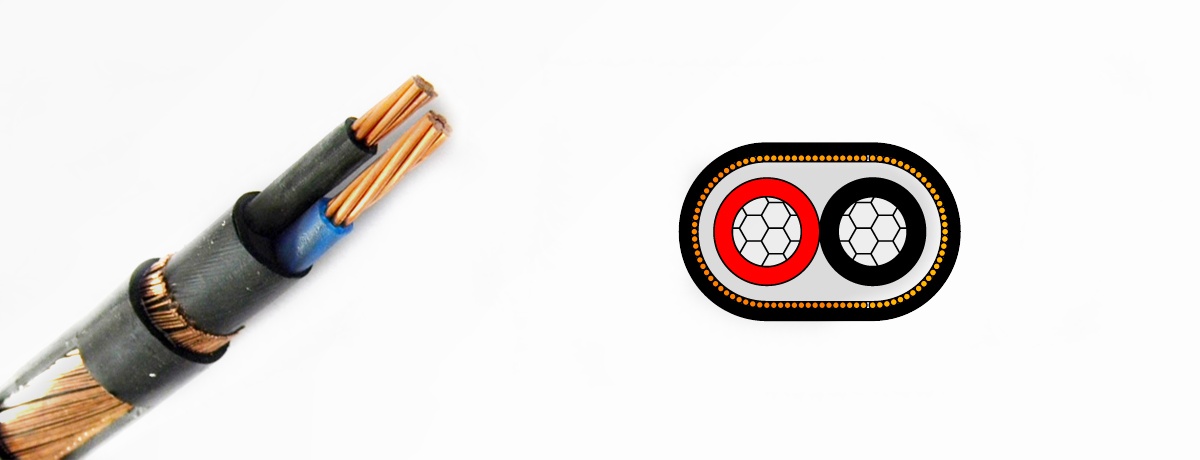

Concentric cable is a type of electrical cable characterized by its unique construction. It consists of one or more conductors, usually copper or aluminum, that are surrounded by layers of insulation and a concentric layer of conductors.

This design typically includes a central conductor, which is encased in an insulating layer. Surrounding this insulation is another layer of conductors, often in a helical or spiral configuration, followed by an outer insulating jacket.

Central Conductor: The primary pathway for electrical current, usually made of copper or aluminum.

Insulating Layer: A non-conductive material that prevents short circuits and protects the conductors.

Concentric Conductors: Additional conductors that wrap around the insulation, providing added functionality and protection.

Outer Jacket: The final protective layer that shields the internal components from environmental factors.

Improved Electromagnetic Interference (EMI) Shielding: The concentric design helps in minimizing EMI, making it ideal for sensitive applications.

Enhanced Mechanical Protection: The layered structure provides robust protection against physical damage.

Better Grounding: The outer concentric conductors can serve as an effective grounding mechanism.

Concentric cables come in various types and models, each designed to meet specific requirements. The primary variations are based on the materials used, construction, and intended applications.

1. Copper Concentric Cable

Copper is renowned for its excellent electrical conductivity, making copper concentric cables a popular choice for many applications. These cables are often used in environments where superior conductivity and durability are essential.

Power Distribution: Ideal for residential, commercial, and industrial power distribution.

Grounding Systems: Used in grounding applications due to copper’s excellent conductivity.

Control Systems: Suitable for control and instrumentation systems where precision is crucial.

Aluminum concentric cables are lighter and often more cost-effective than their copper counterparts. While aluminum has lower conductivity than copper, it’s still sufficient for many applications, especially where weight and cost are considerations.

Utility Services: Commonly used by utility companies for overhead and underground services.

Substations: Suitable for use in electrical substations where lighter cables are preferred.

Industrial Applications: Used in various industrial settings where cost-effectiveness is a priority.

Designed for low voltage applications, these cables are typically used in settings where voltage levels do not exceed 1,000 volts.

Residential Wiring: Used in homes for various electrical wiring needs.

Lighting Systems: Suitable for indoor and outdoor lighting installations.

Low Voltage Control: Ideal for low voltage control circuits in commercial and industrial environments.

These cables are used for applications requiring voltage levels between 1,000 volts and 35,000 volts. They are often found in more demanding environments.

Medium Voltage Distribution: Used in the distribution of medium voltage power.

Underground Systems: Suitable for underground power distribution systems.

Renewable Energy Systems: Used in renewable energy installations, such as wind and solar farms.

High voltage concentric cables are designed for applications requiring voltage levels above 35,000 volts. They are built to withstand high stress and harsh environmental conditions.

Transmission Lines: Used in high voltage power transmission lines.

Industrial Power Systems: Suitable for large-scale industrial power systems.

Electrical Substations: Essential for connecting electrical substations to the power grid.

Concentric cables are versatile and find applications across various sectors due to their unique construction and benefits. Here are some of the most common applications:

Concentric cables are widely used in power distribution networks. Their ability to handle high currents and provide effective grounding makes them ideal for both residential and commercial power distribution.

Reliability: The robust construction ensures reliable power delivery.

Safety: Effective grounding reduces the risk of electrical faults and shocks.

Durability: Designed to withstand harsh environmental conditions.

Effective grounding is critical in electrical systems to ensure safety and proper functioning. Concentric cables are often used in grounding systems due to their excellent conductivity and reliability.

Improved Safety: Reduces the risk of electrical shocks and equipment damage.

Compliance: Meets regulatory standards for grounding systems.

Versatility: Suitable for various grounding applications, including industrial and residential.

In control and instrumentation systems, precision and reliability are paramount. Concentric cables are ideal for these applications due to their ability to minimize EMI and provide accurate signal transmission.

High Precision: Ensures accurate signal transmission for control and monitoring.

EMI Shielding: Minimizes electromagnetic interference, enhancing system performance.

Flexibility: Suitable for various control and instrumentation applications.

The growth of renewable energy systems, such as wind and solar farms, has increased the demand for reliable and durable cables. Concentric cables are well-suited for these applications due to their ability to handle high currents and harsh environmental conditions.

High Efficiency: Ensures efficient power transmission from renewable energy sources.

Durability: Withstands harsh environmental conditions, including UV exposure and temperature extremes.

Scalability: Suitable for both small and large-scale renewable energy installations.

Utility companies use concentric cables for both overhead and underground services. Their reliability, durability, and cost-effectiveness make them an excellent choice for utility applications.

Cost-Effective: Aluminum concentric cables provide a cost-effective solution for utility services.

Reliability: Ensures consistent power delivery to customers.

Versatility: Suitable for both overhead and underground installations.

In telecommunication systems, the quality of the cable can significantly impact performance. Concentric cables are used in various telecommunication applications due to their ability to provide reliable signal transmission and minimize interference.

Signal Integrity: Ensures high-quality signal transmission.

EMI Shielding: Reduces electromagnetic interference, improving communication quality.

Durability: Designed to withstand environmental challenges, ensuring long-term reliability.

Selecting the right concentric cable for your specific application involves considering several factors. Here are some key considerations:

The conductivity of the cable material is crucial, especially for applications requiring high efficiency and minimal power loss. Copper concentric cables offer superior conductivity, while aluminum cables provide a cost-effective alternative with slightly lower conductivity.

The voltage level of your application will determine whether you need low, medium, or high voltage concentric cables. Ensure the cable you choose can handle the required voltage safely and effectively.

Consider the environmental conditions where the cable will be installed. For harsh environments, such as underground or outdoor installations, choose cables with robust outer jackets and materials that can withstand UV exposure, moisture, and temperature extremes.

Ensure the cable meets all relevant industry standards and regulations. This is particularly important for safety and performance, as well as for meeting legal requirements.

Different applications have unique requirements. For instance, telecommunication systems need cables with excellent EMI shielding, while power distribution systems require cables that can handle high currents and provide effective grounding.

Proper installation and maintenance are critical to ensure the long-term performance and safety of concentric cables. Here are some best practices:

Follow Manufacturer Guidelines: Always follow the manufacturer’s guidelines and recommendations for installation.

Use Proper Tools: Ensure you have the right tools and equipment for cutting, stripping, and terminating the cables.

Avoid Sharp Bends: Do not bend the cables sharply, as this can damage the insulation and conductors.

Secure Properly: Use appropriate clamps and supports to secure the cables and prevent movement.

Test After Installation: Conduct thorough testing after installation to ensure there are no faults or issues.

Regular Inspections: Conduct regular inspections to check for signs of wear, damage, or corrosion.

Clean Connections: Ensure all connections are clean and free of debris or corrosion.

Monitor Performance: Keep an eye on the system's performance to detect any potential issues early.

Replace Damaged Cables: Replace any damaged or worn cables promptly to prevent further issues.

Follow Safety Protocols: Always follow safety protocols and procedures during maintenance to protect yourself and the system.

Concentric cables play a vital role in various electrical and communication systems. Their unique construction offers numerous benefits, including improved EMI shielding, enhanced mechanical protection, and better grounding.

With various types and models available, including copper and aluminum options, concentric cables can meet a wide range of application-specific needs.

Whether used in power distribution, grounding systems, control and instrumentation, renewable energy, utility services, or telecommunications, concentric cables provide reliable and efficient solutions.

By choosing the right cable and following best practices for installation and maintenance, you can ensure the long-term performance and safety of your electrical and communication systems.

Understanding the intricacies of concentric cables and their applications will empower you to make informed decisions and optimize the performance of your projects.