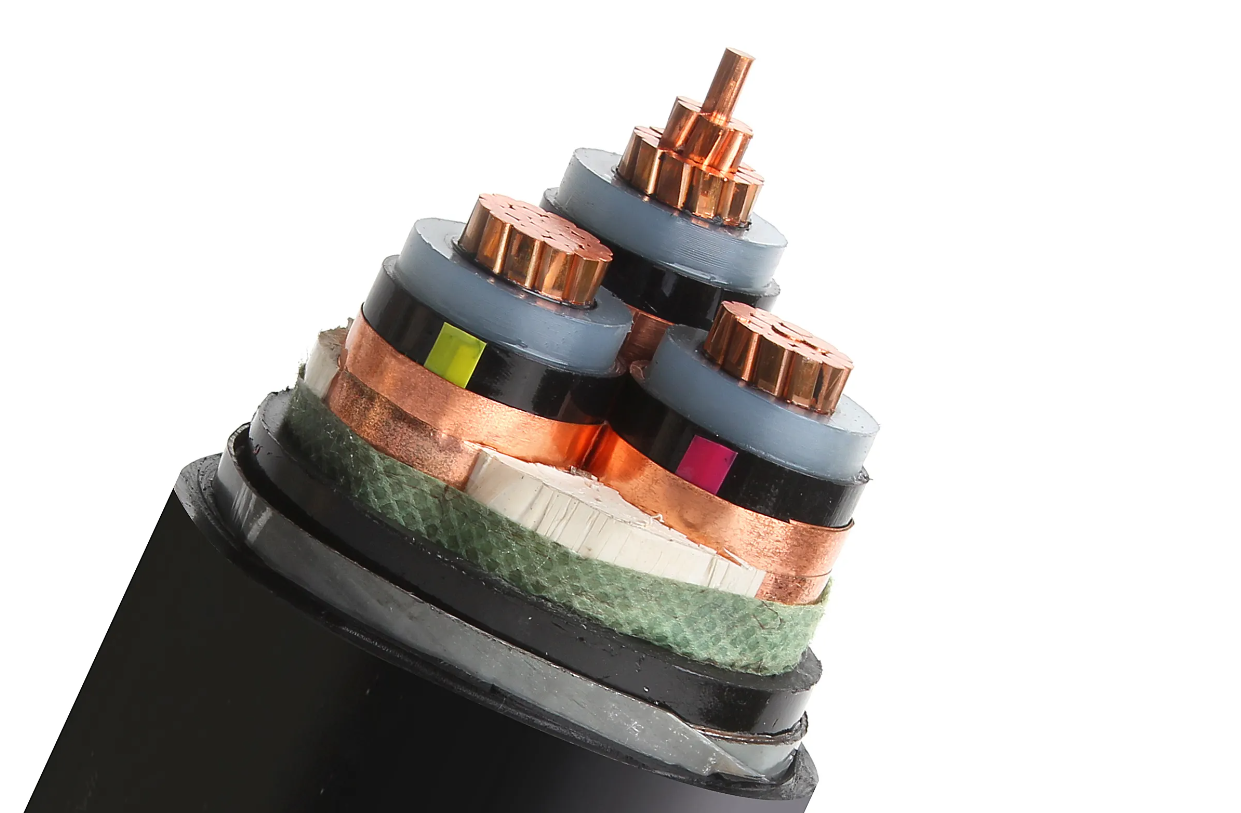

Generally in the cable production process prone to the problem of insulation eccentric, insulation shielding thickness is not uniform.

There are impurities within the insulation, inside and outside the shield has a protrusion, the degree of uneven cross, cable damp, cable metal sheath seal bad, etc.

The site conditions are relatively poor, cables and connectors in the factory manufacturing environment and process requirements are high, and the construction site temperature, humidity, dust are not good control.

The cable construction process in the insulation surface will inevitably leave a small slip marks, semi-conductive particles and sand on the sand may also be embedded in the insulation

Cracking of cables due to thermal expansion of the cable results in breakdown.

When the cross-linked cable load is high, the wire core temperature increases, the cable is heated and inflated, and the cable roof is on the bracket's face in the tunnel.

The long-term heavy-duty running cable has a great creep force, which causes the bracket to crush the cable outer jacket , Metal sheath, squeeze into the cable insulation layer leads to cable breakdown.