Elevators make life easy for everyone. And the most popular elevators that have been helping people save time and energy for decades now are the cable-run elevators.

The elevator cables are to be appreciated here as a special cable for doing the job right and having us all reach heights or lows in just a matter of seconds.

Cable elevators function on a basic principle where the elevator raises with a traction caused by a cable looped sheave which is in turn linked to an electric motor.

As the motor starts turning one side the elevator raises and when the motors turns the other way the elevator is lowered.

And all these are housed in one machine box that is above the elevator shaft.

Elevator cables play an important role in the functioning of the elevators which are more versatile and efficient as compared to the hydraulic ones.

Now one thing that we should note is that the elevator cables are designed specially to withstand high amounts of mechanical stress and interestingly they are a part of the world’s fastest and highest elevators.

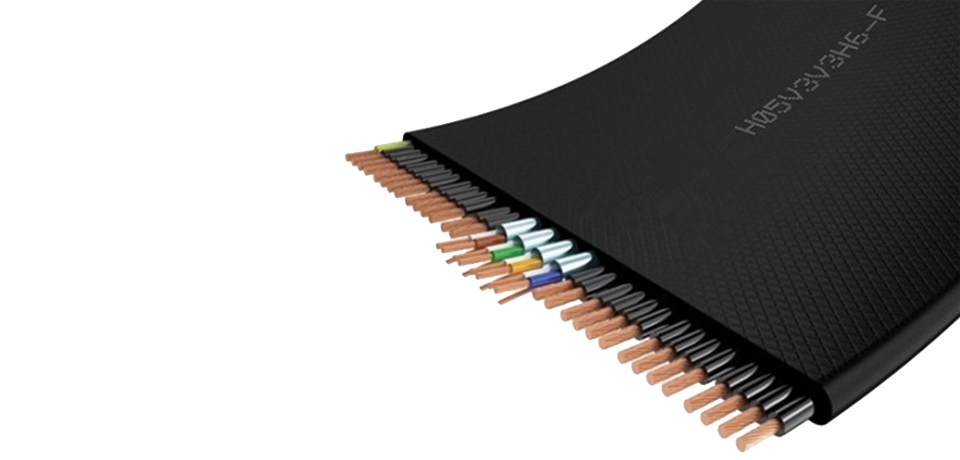

Most of the elevators function through flat elevator cables which are approximately in between 80 meters to 400 meters long depending upon the height of the building or number of floor the elevator has to reach.

Elevator cable is an important connection that links the elevator and the controller and in the traditional elevators the power and signal data in carried through the cable that travels.

All types of lift cables are easy to install and they come with a spectrum of designs to choose and they priced differently based on the materials used.

Most buyers prefer procuring lifts that run on elevator cables for they are durable reliable and can be manually operated easily during power cuts for people to get off it.

And when it comes to choosing the best design or type of the elevator cable the whole decision revolves around cost-effectiveness and reliability.

Now according to the market figures the flat type is relatively lesser than the round cables as the flat ones can form smaller loops than the round ones.

And therefore flat ones are preferred where the loop clearance has minimal space.

On the other hand when it comes to achieving the right number of conductors flat ones are to be combined several times and the single ones can be combined just by a single round.

Therefore apart from just the cost-effectiveness the flat cables and the round cables are to be chosen according to the elevator construction position and the space available for the cable loops.

ZMS cable have grown to be experts in providing exclusive designs to the buyers and the installation has become all the more simple as compared to the earlier times.

Although the manufacturers have a lot of information to bombard the buyer with it’s important that an elevator contractor naturally has greater knowledge of which material is to be used so as to ensure that the utility of the elevator is at its best.