There are two main conductor portion corrosion, chemical corrosion, and electrochemical corrosion.

Chemical corrosion

It refers to the metal in the atmosphere with oxygen, chlorine, sulfur dioxide, hydrogen sulfide, and other gases used to make corrosion under.

After the metal surface with oxygen, generating different metal oxides.

Aluminum oxide can form a dense surface protective film of certain hardness.

Loose iron oxide structure, easy to fall off, and continued penetration of the metal inside, diffusion, material destruction.

Copper oxide, commonly known as Pseudomonas, between above two, is a toxic substance.

Electrochemical Corrosion

It means metal and a dielectric consisting of primary cells, the formation of corrosion of metals, metal when two different electrode potential is connected, there therebetween when water or other electrolytes, will produce a current between the two metals forming a galvanic cell, one of the metal at a positive potential, and the other at a negative potential, at a negative potential of the metal ion state would continue through the electrolyte to the positive potential of metal accumulation in.

So that in the negative potential of the metal gradual loss of damage, the formation of electrochemical corrosion. The difference between the electrode potential of the two metals in the larger, the more intense electrochemical corrosion. The higher the temperature, the metal corrosion is also more serious.

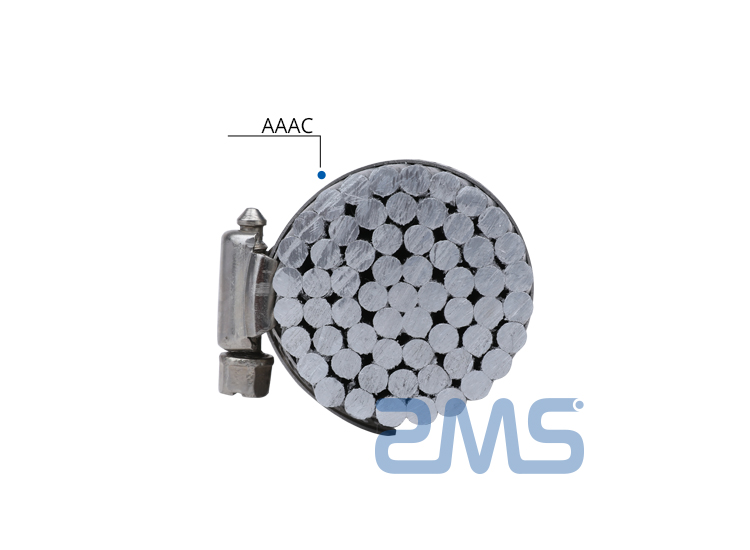

Different metals have different electrode potentials. The common electrode potential of the order of several metals; metal Ag (silver) Cu (copper) Pb (Lead) Sn (tin) Fe (iron) Zn (zinc) A1 (aluminum). Potential + 0.8 + 0.334-0.122-0.16-0.44-0.76-1.33 greater negative electrode potential metal ions into the electrolyte to become a stronger trend, namely the more susceptible to corrosion. Large negative electrode potential of aaac conductor, but often because of its surface an oxide film protective layer, can improve its corrosion resistance.

Adding rare earth elements rare earth alloy material is AAAC conductor, which can purify and improve the purity, to fill surface defects, grain refinement. Reduce segregation, eliminate microscopic effect caused by uneven local corrosion, but also bring more negative electrode potential of aaac conductor, with a sacrifice anode effect and excellent electrical properties, thus greatly improving the corrosion resistance of aluminum. For the marine environment corrosion problems C1- and petroleum, chemical environment, S, H2S + C02, etc., this material has a unique corrosion mechanism.

Strong reduction of rare earth metals can be effectively combined with S, H2S, C1- strong oxidizing interaction, generate a stable compound (C1- and earth aaac conductor to form a stable complex compound), the chemical reaction of oxidation and reduction process organic unity, interaction, as the oxidation activity S, H2S, C1- other corrosive media cause corrosion fundamentally damaged, thus completely solve worldwide including the United States developed countries have failed to solve the problem well by the Beijing Nonferrous Metal Research Institute and other national testing departments detection and engineering data analysis examples show that chloride ions, water, marine atmosphere, salt spray environment (alternating wet and dry), saturated HzS, sulfur and high-temperature, high-pressure environment conditions Corrosion, the rare earth aluminum was zero or nearly zero.