A shield or screen is a material that is electrically conductive and surrounds a wire or cable.

The shield's primary function is to limit any signal trying to escape from the wire or cable.

There are a few basic ways of shields or screens used in the wire and cable industry today.

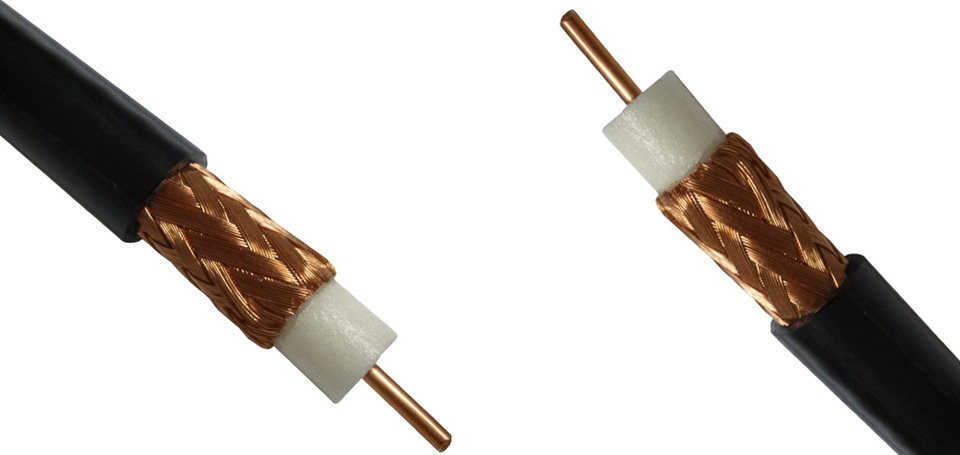

Braid shield: The most common method of shielding, this can be accomplished by crossing layers of individual metal stands (typically copper or aluminum metal) over a cable core or an insulated conductor.

A braid shield consists of groups of tinned or bare copper or aluminum strands, one set woven in a clockwise direction and interwoven with another set in a counterclockwise direction.

Braid shields provide superior structural integrity, while maintaining good flexibility and flex life.

These shields are ideal for minimizing low frequency interference and have lower dc resistance than foil. Braid shields are effective at audio, as well as FR ranges. Generally, the higher the braid coverage, the more effective the shield.

However, the trade-off between cost and braid coverage must be considered.

Typical braid coverages are between 80% and 95%. Coverage of 100% is unattainable with a braid shield.

Other features to consider when choosing a braid shield are the weave angle, strand diameter, number of carriers (strand groups) and the number of ends (strands).

Braid shields are generally bulkier and heavier than other shields and, in some cases, harder to terminate because the braid must be combed out and pigtailed.

Serve or Spiral Shield: Spiral Shields can be manufactured by applying metallic strands in a helical fashion around a cable core or an insulated conductor.

This is similar to a braid except that it is made up of single strands of wires spirally wrapped around a conductor or cable core.

This type of braid is more flexible than a woven braid. It is also easier to terminate than the woven braid.

Spiral shields typically have a nominal coverage of 95% to 98%. Spiral shields are most effective in the audio frequency range and are typically found in microphone and audio cables.

Tape shield: These are made from various materials.

They normally consist of a laminate of aluminum and polyester layers joined together by adhesive.

These types of shields are fragile and provide little in the way of mechanical strength.

The adhesive is typically a pressure sensitive solvent release adhesive.

Listed below are some of the more popular ones used today:

o Aluminum/Polyester

o Aluminum/Polypropylene (AP)

o Aluminum/Polyester/Aluminum (APA)

o Foil Free Edge

o Bonded