The main means used by unscrupulous manufacturers is to make an article on the length of the wire and cable.

The actual length of the wire and cable is less than the nominal length, and the pricing is performed according to the nominal length.

The most typical one is the cloth wire wrapped in a roll.

In the standard, 100 meters per roll, the measurement error is not more than 0.5%, that is, the length of each wire is 100±0.5 meters, and many cable manufacturers are blatantly on the qualified card. Marked 100 ± 20 meters, the actual length is only about 80 meters, if its price is equivalent to each meter, it is not cheap.

Such scams are easier to identify, one is to see the qualified card.

The second is the length of the check because the cloth wire is relatively soft and easy to measure.

A wire with a resistance value exceeding the standard may have a temperature that is too high at the same current, thereby accelerating the aging of the outer insulation layer, and causing a short circuit to cause a fire.

And because the resistance exceeds the standard, the power consumption of the transmission process is greatly increased, and the electricity cost is increased.

The first is the idea of copper conductors.

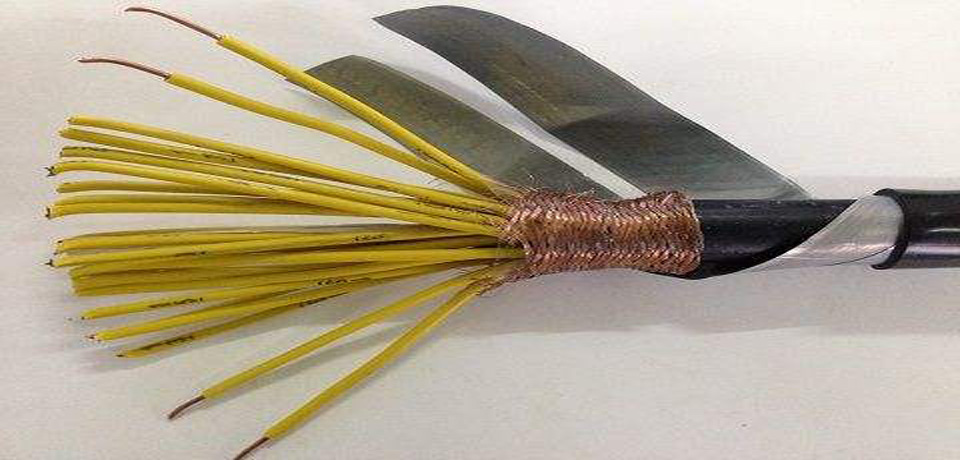

Copper conductors account for 80% of the cost of wires. One of the bad manufacturers is reducing the quality of copper.

With the use of much lower-priced impurities such as copper, copper recovery, and even copper smelting, the copper content is extremely unstable, resulting in a large increase in the electrical resistivity of copper conductors.

The second is to reduce the amount of copper used.

Reducing the actual cross-sectional area of the copper core, the direct consequence of these two practices is that the wire overheats during use, damaging the insulation plastic, causing a short circuit, and causing a fire.

The second is to use the plastic used in the insulation layer to break the heart and the same quality as the copper material.

The price difference between the ton of recycled insulation material and the qualified PVC plastic powder is nearly 2,000 yuan, but the recycled insulation material has high impurity content and low mechanical strength.

The aging resistance and electrical insulation performance are degraded, which will directly lead to electric wire leakage.

The content of the wiring certificate issued by the regular manufacturer shall include certification mark, certification number, model specification, implementation standard, rated voltage, wire length, production date, producer, inspector, factory name, site, fixed telephone, anti-counterfeiting mark, etc. The labels of counterfeit products are often unclear or incompletely printed.

The plastic outer skin of the regular wire is soft and smooth, and the color is uniform.

On its surface, it should also be printed with several items on the product certificate, such as certification mark, certification number, model number, rated voltage, implementation standard, factory name, etc. At the same time, the writing must be clear and not easy to wipe off.

It is advisable to repeatedly bend a wire head by hand. Anyone who has a soft hand feeling, good fatigue resistance, strong plastic or rubber feel and no crack on the wire insulation is a superior product.

The fake wire insulation layer looks very thick. In fact, it is mostly made of recycled plastic. As long as it is squeezed slightly, the extrusion will be white, and the wire will be broken 4 to 6 times.

High-quality insulation materials have a certain degree of mechanical strength and flexibility, and can not be easily peeled off. Inferior wires can be torn off or smashed down by hand.

The insulation layer of the wire has a certain flame retardancy. Peel off a section of insulation, ignite with a lighter, and continue to spontaneously ignite after the open flame is inferior.

Macro cable

Take a section of the insulation layer and see if the section of the insulation layer has visible pores, and whether the core is located in the middle of the insulation layer.

The non-centered one is due to the eccentricity caused by the low process, and the pores indicate that the insulating material used is unqualified. The eccentricity is most likely to leak electricity on the thin side, and the pores also affect the compressive strength.

The color of high-quality copper wire is bright red, and the inferior copper core is purple, black, yellow, or white, with high hardness, many impurities, poor mechanical strength, poor toughness, and will break when pressed a little.

And there are often broken wires in the wires.

For a multi-strand soft wire, touch the top of the copper wire with the palm of your hand. It feels flat and has no tingling sensation and is soft to the touch. Otherwise, it is a poor-quality wire.