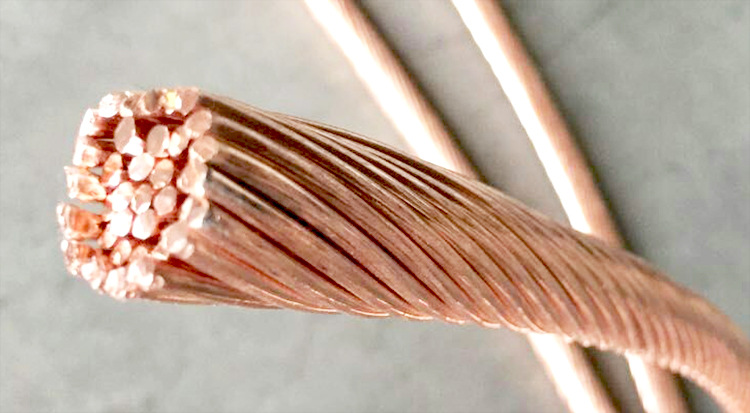

The bare conductor has a hidden, and it is possible to make the appearance of the building, the ground, and the environment look more beautiful, but because this feature also brought the difficulty factor is difficult to detect failures and processes high. Hazards caused by mechanical problems can be discovered and resolved within the appropriate time, but hidden problems in production, installation, laying, and environmental and other causes must be fault finding process to find fault and solve problems.

Lie in the bare conductor fault finding obstacles in front of the three factors apparatus, search method, and personnel. In real-time find, if not able to deal with the problem, or do preparedness, it will make the whole situation worse, worse it is to make the staff may be in jeopardy. On the basis of these three areas, the paper analyzed deep to find out what the bare conductor troubleshooting process must pay attention to.

1. The device.

In the current situation, by using a bare conductor fault finding equipment range is divided into general-purpose equipment and special equipment for two device types. General equipment mostly measures meter, which contains the cable insulation shake test instrument (megohmmeter), multimeter, special equipment is mostly instruments, including fault distance meter, fixed equipment, PathFinder instrument, high voltage discharge, and control means cable identification instrument and bare conductor puncture and so on.

Each production business is trying to make its own production facilities have more integrated, more compact, and easier advantages, but in the use of the engineering process, the device still needs a lot to deal with complex and diverse types of faults. These devices often occur following describes three types of questions in practical use.

With the rapid development of technology, extensive use of old-time distributed devices gradually being more lightweight, integrated devices instead. The new device does have a lot of strengths, such as high labor efficiency, the search time is short, wiring error probability is low, but many manufacturers in order to make the device more lightweight advantages, forcibly cut wire sections with the capacitance of the capacitor, the wrong approach to make In reality, the use of equipment is often because the current is too large, too long discharge burning reason to be destroyed.

In addition, many manufacturers are irresponsible for electronic components, integrated circuits, and related materials model such things be concealed, when equipment problems when the consumer is no way to repair it, the only way is the Depot Maintenance has extended the processing time of the failure so that the operation and management of capital cost overruns.

2. There are problems in the scope.

Various manufacturers of equipment in roughly the same part of the production principle, but the type of components used in every aspect but the future, will lead to loosening interface, thus making the interface generate a very high impedance, heat increases. Therefore, the use of an infrared thermometer found that if the temperature rises to a certain value, it should appear in the timely processing of a loose interface.

Normally that if the measured infrared thermometer temperature is higher than the ambient temperature by more than ten degrees, it finds a problem with the electrical connections, if the measured temperature is thirty degrees higher than the ambient temperature, the determined temperature is very serious and must be timely dealt with.

3. Application of infrared temperature measurement.

Infrared detection technology continues to mature, and accurate test results, high precision, and therefore can be widely used in the power system. Now not only a bare conductor to detect the temperature of the infrared detector, or advanced diagnostic technology, by analyzing temperature and the temperature distribution was found inside the device defects and risks.

Infrared temperature measurement in electrical systems as well as other applications, such as unmanned substation infrared thermometers can be used for security and early warning. If the substation on duty leaves and enables the infrared thermometer, timely warning by sensing the temperature of the body. An infrared thermometer is widely used, but we can not list them here.