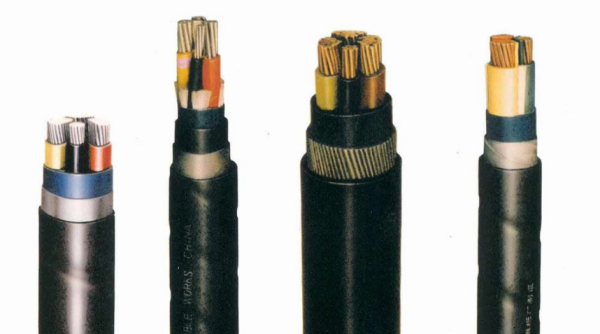

Wire and cable is the main carrier of power transmission, and their use range is extremely wide, especially in the “city network, rural network” transformation, and new construction projects.

Do the following analysis and identification of some inferior products.

According to reports, inferior wires have great harm.

The first is the low-security performance.

The insulation layer with many wires is not made of regular insulating plastic but is made of recycled plastic.

The insulation layer can be peeled off by peeling off, which is easy to cause the insulation layer to be broken by the current leakage.

Life safety poses a great threat.

Secondly, the thickness of the conductive inner conductor determines the load of the wire on the current.

The larger the current, the thicker the conductive core is required.

During the inspection, it was found that the actual cross-section of the core of many wires is much smaller than the size indicated.

For example, many wires are said to have a core section of 4 square millimeters, but only 2.5 square millimeters are measured, and some even have 1.5 square millimeters.

When consumers use this product, it will cause excessive resistance to heat and cause an electrical fire hazard.

(1) Look at the printed words on the label and the insulation skin.

If there are typos or the printing is different in-depth and the typeface is ambiguous, attention should be paid.

(2) Using the fingers to insulate the outer skin, some inferior insulated wire sheaths are easy to fade, especially in the red line.

This problem is caused by the color of the lines on the fingers or the words on the printed lines.

The general is inferior quality.

(3) Using nails to cut and smash the outer skin, it is generally inferior lines that can be drawn down and smashed down.

(4) Repeatedly bending the insulated wire, the inferior wire insulation layer is generally poor in material, and the insulation layer will be broken after bending 3 to 4 times.

(5) Lgnite the insulation layer, which is inferior to spontaneous combustion after leaving the open flame.

(6) Look at the core color, the inferior line color is gray and has no metallic luster.

(7) In the length of the package, generally 100 meters per tie or circle, the national allowable error is ±0.5%, and the length of the inferior wire is only 95 meters, or even less.

Some are misleading in the package on the basis of "code".

(8) If it is still undetermined by the above seven methods, it is also possible to measure the outer diameter of the insulated wire and the core diameter.

The measured values differ greatly, basically the inferior insulated wires.

(NOTE: There are many bad manufacturers at present, the conductors do not have enough cross-section, Increase the thickness of the insulation or sheath to reach the entire outer diameter of the wire to deceive the user).