In the low-voltage distribution network, the power loss is very alarming.

From the point of view of loss reduction and energy saving, consider the selection of conductor cross-section in the distribution network, under the principle of economic rationality, appropriately increase the cross-section of the conductor to reduce the loss of electrical energy, so as to achieve the purpose of more supply and less loss.

Conductor cross-section of the conductor cross-section is usually determined by the thermal conditions, mechanical strength, economic current density, voltage loss, the conductor's long-term allowable safe load capacity, and other factors.

But from the principle of energy saving, should be "power loss" as the primary basis for selecting the cross-section of the wire.

Low-voltage distribution line conductor selection, first from the following four aspects to consider the choice:

1 The allowable current carrying capacity of the conductor is greater than the load calculation current.

2 Conductor specifications shall not be smaller than the minimum specifications specified in the code.

Mainly from mechanical strength considerations.

3 Laying environmental conditions, such as buried cable must use armored, outdoor open-air must use weatherproof type.

4 Cable-rated voltage and system voltage match.

In the selection of the cross-section, we should also first understand what are the categories of low-voltage overhead conductors.

1 Bare Conductor

Bare wire: made of aluminum, copper, or steel, there is no outer covering, and the conductive part can touch or see.

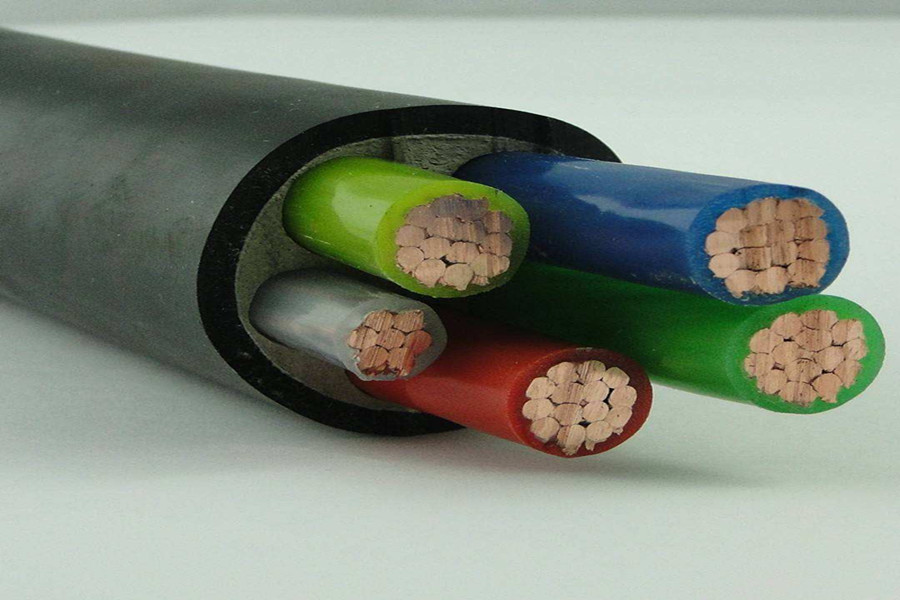

2 Insulated Conductor

Insulated wire: by the conductive core and the absolute green outer skin of the two parts: core made of copper or lead, skin made of plastic or rubber, conductive parts.

The conductive part of the invisible, can not be touched. Insulated wire.

How to correctly select the conductor cross-section for low-voltage overhead lines?

The section of low-voltage overhead line conductors is generally selected according to the following conditions:

When the wire continuously passes the maximum allowable load current, the wire heat does not exceed the allowable temperature of the wire core.

The voltage loss generated when the conductor continuously passes the normal maximum load current cannot exceed the allowable range to ensure the normal operation of the electrical equipment.

The “National Electricity Supply Rules” stipulates that the voltage variation range of low-voltage power users is ±7% of the rated voltage, and that of low-voltage lighting users is +5% to -10% of the specified voltage.

The wire should be prevented from being installed or operated.

For low-voltage overhead line conductor cross-section, aluminum stranded wire is required to be not less than 25mm2, and steel-cored aluminum stranded wire is not less than 25mm2.

And copper wire diameter is not less than 4mm.

When selecting a larger conductor cross-section, consideration should also be given to choosing according to the economical current density to reduce the power loss and operating costs of the circuit.