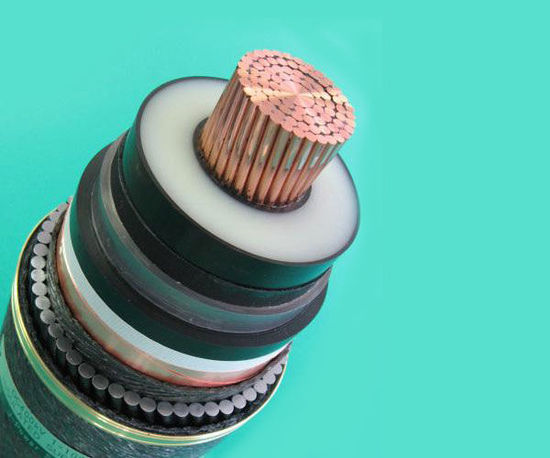

With the advancement and development of society, the demand for cables is increasing. Especially for medium and pvc copper wires ,0.6/1kv xlpe armoured copper cable ,medium voltage xlpe cable ,aerial bundled cable abc cable,aaac ,acsr,aac are very popular in the market.

It is necessary to strictly control the quality of raw materials procurement, production, transportation, sales, etc., and strictly control the procurement of raw materials. For suppliers, the products are better than the quality, price, service and goods. It has high quality and low price of raw materials, and has a production line of 10,000 tons of oxygen-free copper rods, wire drawing branch, plastics branch, and rubber rolling plant. It has the ability to continuously produce from the initial stage, which is of high quality and low price. The product provides a guarantee.

Wire and cable manufacturing uses special production equipment with the characteristics of the industry to meet the structural and performance requirements of cable products, meet the requirements of large-length continuous and as fast as possible production, thus forming a series of special equipment for cable manufacturing. Such as extrusion machine series, wire drawing machine series, stranding machine series, winding machine series.

In the production process, the income of the staff of the production line is directly linked to the quality of the product. The work assessment of the person in charge of the production line workshop is directly linked to the quality. Each process has a strict operating procedure and quality responsibility system. The quality inspection department shall use advanced instruments and scientific testing methods to regularly inspect the products on the production line.

The inspectors shall take samples. After the measurement, the team leader shall sign and record and notify the first-line production personnel. The production line has non-conforming products, and the on-duty personnel cannot leave. Gang. Unscheduled sampling of products that are not in stock for each batch. The technicians of the company's inspection department use professional instruments to inspect the finished products according to the strict rules of quality control.

When the custodian receives the product into the warehouse, it also conducts random inspection on the wire diameter, length, sheath, insulation and adhesion of the product. If it is found that the national standard is not up to standard, it can refuse to enter the warehouse and request the quality inspection department to re-examine.

Quality has always been the soul of ZMS cable. We strictly control the quality. All cables are quoted based on international standards and have to pass strict inspection before shipment.