SUBTITLE: Power Cable structures are simple and complex. They include conductor, metal shield, Semi-conductive shield, insulation, and cover.

ABSTRACT: The components of the cable structure are subject to strict requirements and regulations and are strictly enforced according to the standards.

Each structure has its own characteristics and uses. For detailed analysis, please see the following article

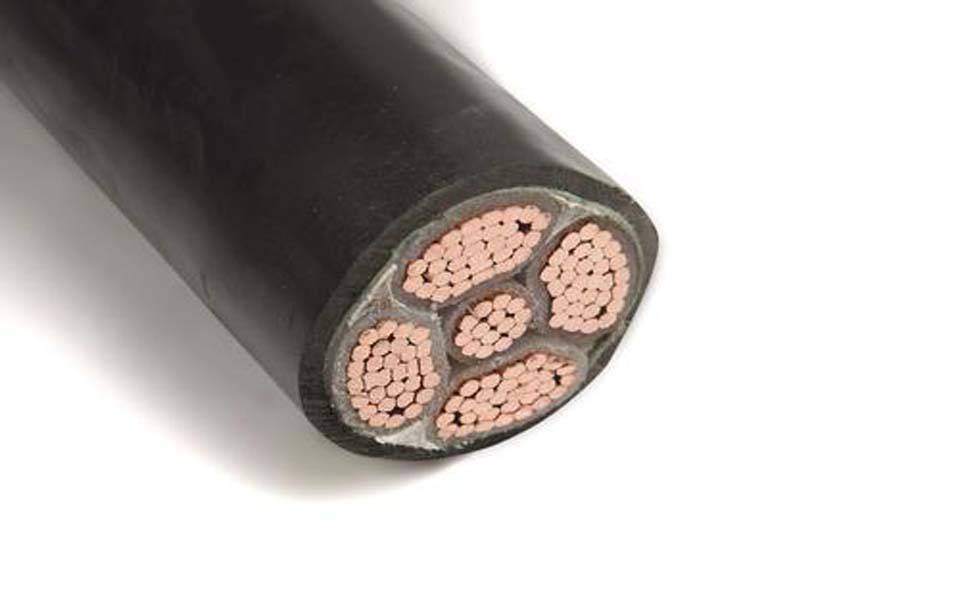

CONDUCTOR

The conductor is the path that provides the load current. Its main technical indicators and requirements:

1) Conductor Cross-Section and DC Resistance: Since the current passes through the conductor, heat is generated due to the resistance of the conductor.

Therefore, the appropriate conductor cross section should be selected according to the amount of the delivered current, and the DC resistance should meet the specified value to meet the heat of the cable during operation. Stable requirements.

2) Conductor Structure: The conductor is also a high-voltage electrode when the cable is working, and its surface electric field intensity is the largest.

If there is a local burr, the electric field strength at this place will be greater.

Therefore, one of the main technical problems to be solved in the design and production and in the use of the conductors in the production of joints is to try to make the conductor surface as smooth and round as possible without burrs to improve the electric field distribution on the conductor surface.

METAL SHIELD

The role of metal shielding:

1) The low-voltage electrode forming the working electric field will also form a large electric field strength when there is a local burr.

Therefore, it is also necessary to make the surface of the conductor as smooth and round as possible without a burr.

2) Provides a path for capacitor current and fault current, so there are certain cross-section requirements.

SEMI-CONDUCTIVE SHIELD

The semi-conductive shielding layer is an important technical measure for improving the electric field distribution on the surface of the metal electrode and improving the electric strength of the insulating surface.

1) Firstly, instead of the conductor, a smooth and rounded surface is formed, which greatly improves the surface electric field distribution.

2) At the same time, it can be in close contact with the insulation, overcoming the weak point where the insulation and the metal cannot be in close contact to generate an air gap and shield the air gap from the working field strength.

INSULATION

Insulation is the key structure to reliably isolate the high-voltage electrode from the ground electrode.

1) Withstand the long-term effects of working voltage and various over-voltages, so its electric strength and long-term stability are the most important part of ensuring the entire cable completes the transmission task.

2) It can withstand the heat of the heating conductor and maintain the required electric strength.

Advances in cable technology are primarily determined by advances in insulation technology.

From production to operation, most of the test and measurement projects are aimed at monitoring the various properties of insulation.

COVER

The sheath is an important guarantee for the protection of the insulation and the normal and reliable operation of the entire cable.

Designed with a corresponding sheath structure for various environmental conditions.

Mainly mechanical protection (longitudinal, radial external force), waterproof, fireproof, anti-corrosion, and anti-biological. Various combinations can be made as needed.