The power cable generally consists of a core, an insulating layer, and a protective layer.

The core is used for conducting electricity; the insulating layer is used to insulate the core conductor from the protective layer to prevent leakage; the protective layer is used to prevent damage to the cable insulation and moisture, and prevent the outflow of liquid insulation (insulating oil).

The core of the core cable has two kinds of copper core and aluminum core.

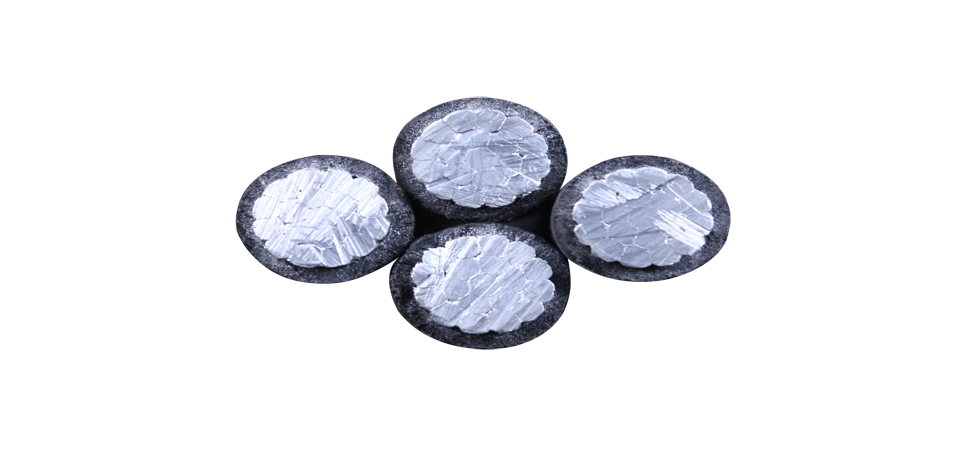

The core cross-section has three shapes: round, semi-circular, and fan-shaped. Three-core and four-core low-voltage cables use fan-shaped cores.

Depending on the type and specification of the cable, the core can be made into a single strand or a stranded core.

The stranded core is made up of a single strand and a single strand.

(1) Oil-paper insulated cable is mainly divided into two types:

viscous impregnated paper insulation and non-drip flow. It is generally used in the 3-35KV systems.

Viscous impregnated paper insulated cable:

simple structure, convenient manufacturing, low price, easy to install and maintain, long life; not suitable for high drop laying, insulating oil is easy to flow.

Non-drip impregnated paper insulated cable; the cost is slightly higher than the adhesive paper insulation, the working life is longer, and the high drop can be laid.

(2) Commonly used plastic insulated cables are cables such as polyvinyl chloride, polyethylene, and cross-linked polyethylene.

1) PVC Insulated Cable.

The installation process is simple, the laying and maintenance are convenient, can be adapted to the high drop laying, and has non-combustibility; the working temperature has a significant influence on the mechanical properties.

Generally used in 6KV and below systems.

2) Polyethylene Insulated Cable.

It can be applied to high drop laying, good process performance, and easy processing, but it is easy to prolong combustion, heat is easy to deform, and stress cracking is easy. Less used.

3) XLPE Cable.

The cross-linked polyethylene cable allows higher temperature rise, so it allows larger current carrying capacity and good heat resistance.

It is suitable for high drop placement, easy installation and maintenance, poor resistance to corona, and free discharge.

XLPE cables are now more widely used and are suitable for a wide range of voltages.

(3) Rubber-Insulated Cable

The rubber insulated cable has good flexibility, is easy to bend, has elasticity, and is suitable for multiple disassembly and assembly of the circuit, but has poor resistance to corona, ozone, heat, and oil, so it can only be used as a low voltage cable. Protective layer structure In order to prevent mechanical damage, electrochemical corrosion, and moisture intrusion, the cable core and the insulating layer of the power cable have a strict protective layer.

The protective layer structure of the power cable is described by taking the XLPE insulated and PVC sheathed power cable as an example.

The outer surface of the conductor is covered with a semiconductor shielding layer, called an inner semiconducting shielding layer, for preventing electric field decomposition and corrosion caused by the long-term action of the electric field of the conductor on the crosslinked polyethylene insulation.

In addition to the cross-linked polyethylene insulation, a layer of semiconductor shield is also covered, called an outer semiconducting shield.

There is a layer of copper tape shield outside the outer semiconducting shield.

Their role is to weaken the effect of the external electric field on the cross-linked polyethylene to ensure good insulation performance.

The copper tape shield is also used as a solder joint for the cable protection ground.

In addition to the copper strip shield, the three cores are filled with fillers, and the outer layer is a three-phase turn-up ladle and a PVC outer sheath.