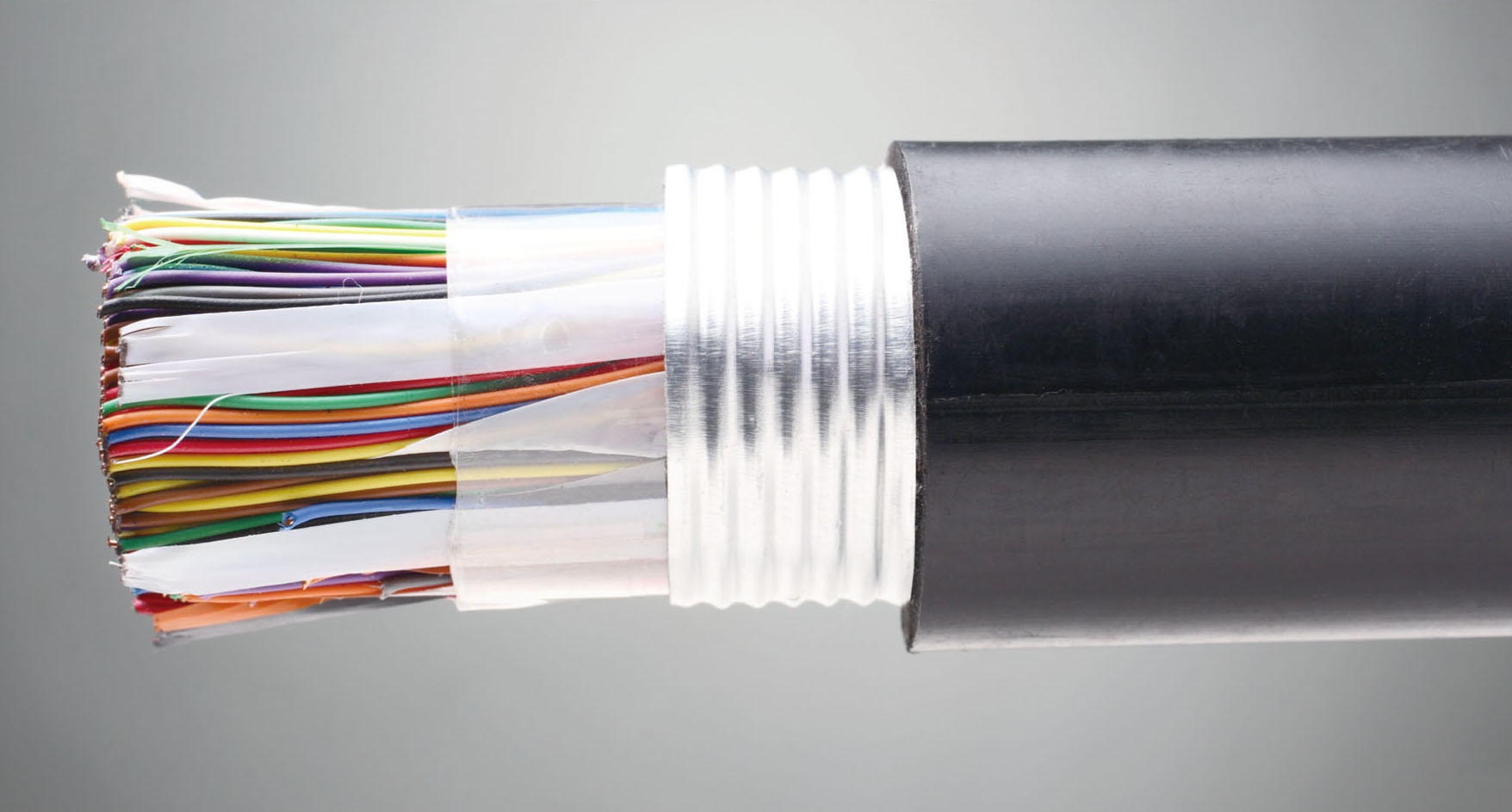

Armored refers to the cable that needs to withstand large mechanical force should have an armored layer, which is a layer of metal protection on the outermost part of the product to prevent the internal utility layer from being damaged during

transportation and installation.

Under the cable forging layer, there should be 1 layer of extruded or wrapped inner lining layer which meets the required thickness.

When the lead-sheathed cable requires armoring, it should be used to wrap with the bedding layer.

If the isolation sleeve is used under the armor layer, it can be replaced by or attached to the inner liner layer.

Armored cable, also known as PVC insulated PVC sheathed steel belt armored power cable, is a kind of cable that can be buried directly in the ground.

Armored cable in the mechanical protection layer can be added to any structure of the cable to increase the mechanical strength of the cable and improve erosion resistance.

It is the wire and cable designed for the area which is vulnerable to mechanical damage and erosion.

The cable can be laid in any way, more suitable for direct burial in rocky areas, the main function is to prevent rat bite.

Among the common power cables, the market price of armored cables is higher than that of non-armored lines.

Because armored cable non-armor cable has an extra layer of protection, so as to protect the cable will not be external mechanical damage, chemical gas corrosion, etc., the natural price is more expensive, but the armored power cable is

generally used in high-rise buildings.

General indoor places do not need armored cable.

The purpose of cable with an armor layer is to enhance the tensile strength, compressive strength, and other mechanical protection to elongate the service life and improve the cable's anti-interference performance through shielding protection.

Commonly used armored materials are steel belts, steel wire, aluminum belts, aluminum tubes,s and so on.

Among them, steel belts and steel wire armor layers have high permeability and good magnetic shielding effect.

It can be used to resist low-frequency interference and can make the armored cable laid in direct burial without the need to wear pipe and cheap and good quality in the actual use of more.

The purpose of power line transmission electric power cable plus armor layer is not only to enhance the tensile strength, compressive strength, and other mechanical protection elongated life but also to prevent some rats from tearing and not to

cause power transmission problems through the armor.

The bending radius of the armor should be large, and the armor layer can be grounded to protect the cable.

After the conductor is energized, the electrical resistance consumes electrical energy and generates heat, which will affect the performance life of the insulation and protection layer materials as the temperature rises.

To make the cable run efficiently, the conductor cross-section should be increased. But the large cross-section of a single conductor is not easy to bend, has poor flexibility, and is very unfavorable to the production of transport and installation,

and laying.

From the mechanical properties and require flexibility and reliability, multiple single wires twisted together stranded, which in turn can solve the contradiction.