Quality inspection departments to tours of inspection for the whole production process, operating self-checking, up and down process inspection.

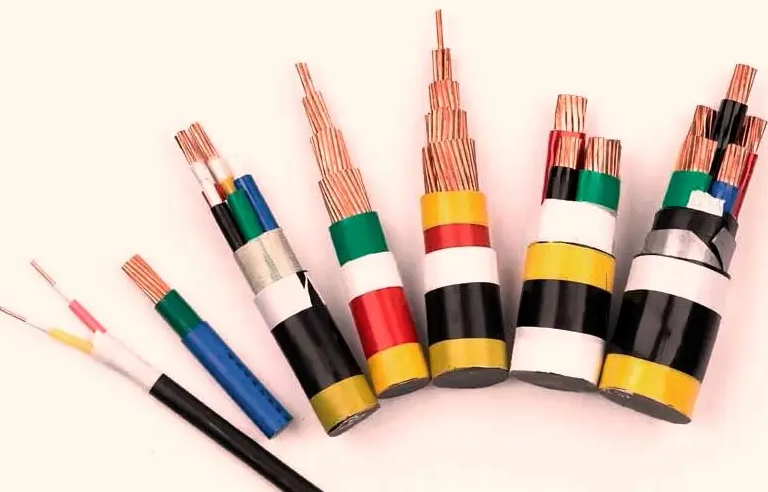

Categories of wire and cable manufacturing process widely, from non-ferrous metal smelting and processing pressure, the plastic, rubber, paint and other chemical technology.

Fiber material around the bag, weaving and other textile technology, to around the package of metal materials and metal strip is applied to longitudinally wrap, welding of metal forming process, and so on.

Wire and cable used in the manufacture of various materials, not only the categories, many varieties, specifications, and large quantities.

As a result, the amount of all kinds of material, spare capacity, batch of material cycle and batch must be approved.

At the same time, the decomposition of waste treatment and recycling, reuse, and waste treatment, as an important content of management, to do a good job of material ration management, attaches great importance to save.

Wire and cable production, from raw materials and various auxiliary materials in and out, storage, processing of semi-finished products circulation to product storage, delivery, material flow is big, must be reasonable layout and dynamic management.