In today's interconnected world, cables play a crucial role in transmitting electrical signals and data.

Two commonly used types of cables are armored cables and ordinary cables.

While both serve the purpose of carrying electrical currents, they differ significantly in terms of construction, durability, and applications.

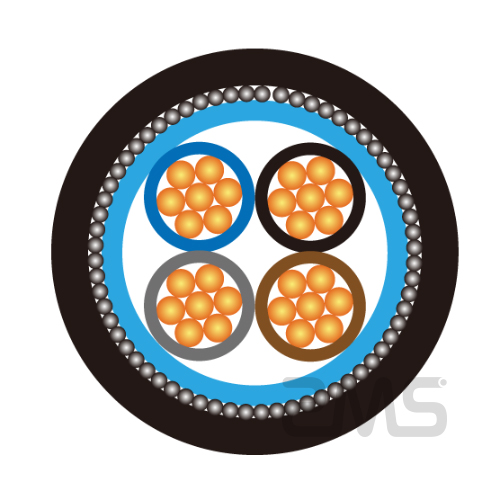

Armored cables, also known as armored wires, are specially designed to provide enhanced protection against physical damage, moisture, and extreme environmental conditions.

They consist of multiple layers of protective materials such as metal sheathing or armor that shields the internal conductors from external hazards.

This robust construction makes armored cables ideal for installations where mechanical strength is critical, such as industrial settings or underground wiring.

On the other hand, ordinary cables are typically constructed with a single layer of insulation around the conductors.

They lack the additional protective layers found in armored cables but are more flexible and cost-effective.

Armored cables and ordinary cables differ significantly in their construction, functionality, and applications.

Firstly, armored cables are designed with an additional layer of protection, usually metal or polymer armor, providing enhanced durability and resistance to external factors such as moisture, vibrations, and physical damage.

In contrast, ordinary cables lack this protective layer and are more susceptible to wear and tear.

Secondly, armored cables are commonly used in harsh environments where there is a higher risk of mechanical stress or exposure to extreme temperatures. They are ideal for outdoor installations or industrial settings where ruggedness is essential.

On the other hand, ordinary cables are typically used in standard indoor applications where minimal protection is required.

Lastly, due to their superior strength and durability, armored cables have a longer lifespan compared to ordinary cables.

Armored cables, with their enhanced durability and protection, find extensive applications across various industries.

One prominent sector is the construction industry where these cables are crucial for ensuring safe and reliable electrical installations.

The robust armor shielding shields the cables from potential damage caused by heavy machinery or accidental impacts, making them ideal for underground or outdoor installations.

In the oil and gas industry, armored cables are indispensable due to their ability to withstand extreme conditions such as high temperatures, pressure, and chemical exposure.

They are widely used for power transmission and control systems in offshore drilling platforms, refineries, and petrochemical plants.

Moreover, armored cables are extensively employed in transportation infrastructure including railways, airports, and highways.

Their ability to withstand vibrations, mechanical stress, and environmental hazards makes them suitable for powering signaling systems, surveillance cameras, lighting fixtures as well as communication networks.

Armored cables offer several advantages when compared to ordinary cables.

Firstly, their armored construction provides enhanced protection against physical damage, such as impact, crushing, or penetration by sharp objects.

This makes them ideal for installations in rugged environments or areas with high foot traffic.

Additionally, armored cables are more resistant to moisture and chemicals, ensuring reliability even in harsh conditions. Furthermore, armored cables provide improved electrical performance due to their superior shielding capabilities.

They offer excellent electromagnetic interference (EMI) and radio frequency interference (RFI) protection, minimizing signal distortion and ensuring reliable data transmission.

Despite these advantages, there are a few disadvantages associated with using armored cables. Firstly, they tend to be heavier and bulkier than ordinary cables due to their added protective layers.

This can make installation more challenging and increase the overall cost of the project.