Due to the weight advantage compared with copper conductors, AAC Conductors in engineering units and lower transportation funds also have certain advantages. "With the continuous improvement of the human cost of the project as well as the requirements of the increasingly tight schedule, there AAC Conductor cables, just adapted to this demand.

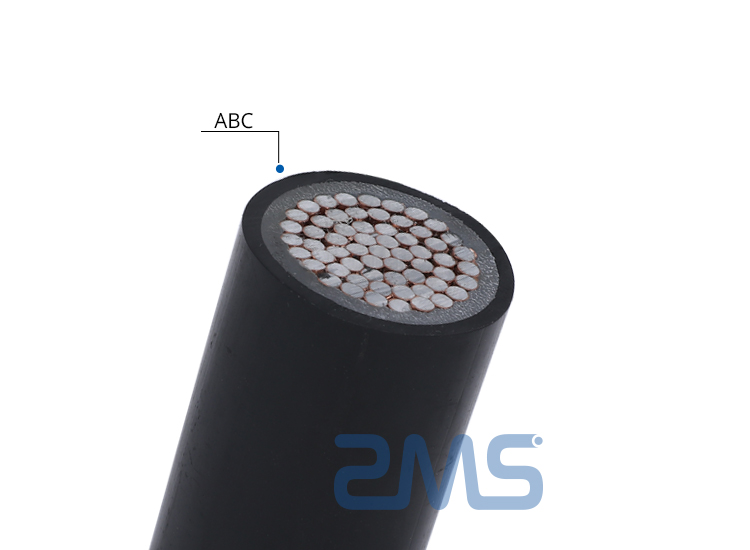

Significantly reduce the weight, but also reduces the requirements for cable retention bracket, bridge, and other materials, while installation of the cable is also more diverse, and even a simple clamp fixed to the wall for surface, to meet the same conductive properties of the premise, and the AAC Conductor cable is only half of the same carrying capacity of copper using AAC Conductor copper cable replacement can reduce cable weight, lower installation costs, reduce equipment wear and cables. At the same time, much more than copper AAC Conductor is flexible and has good bending performance, there is a smaller bend radius during installation, and terminal connections are easier. "Liu Bin said.

The above view is shared by other industry experts. Director of the national wire and cable for Quality Supervision and Inspection Center Wu Changshun believes AAAC Conductor material due to increased iron, silicon, magnesium, and other trace elements in aluminum and after the formation of the disposal process, greatly improves the bending aluminum, corrosion resistance, mechanical processing, heat resistance, mechanical strength, and other properties.

In addition, the cost advantage but also to the aluminum conductor cables "capital" to upgrade. Since 2013, copper price of about 50,000 yuan / t or so, aluminum is about 10,000 yuan / t, copper and aluminum price is only about 1/4 of the same electrical properties under consideration, only the weight of aluminum 1/2, that is, if the use of AAC Conductor, the aluminum conductor copper price is only 1/8 of the price of copper conductor, the price difference is huge.