In the power line, the proportion of cables is gradually increasing.

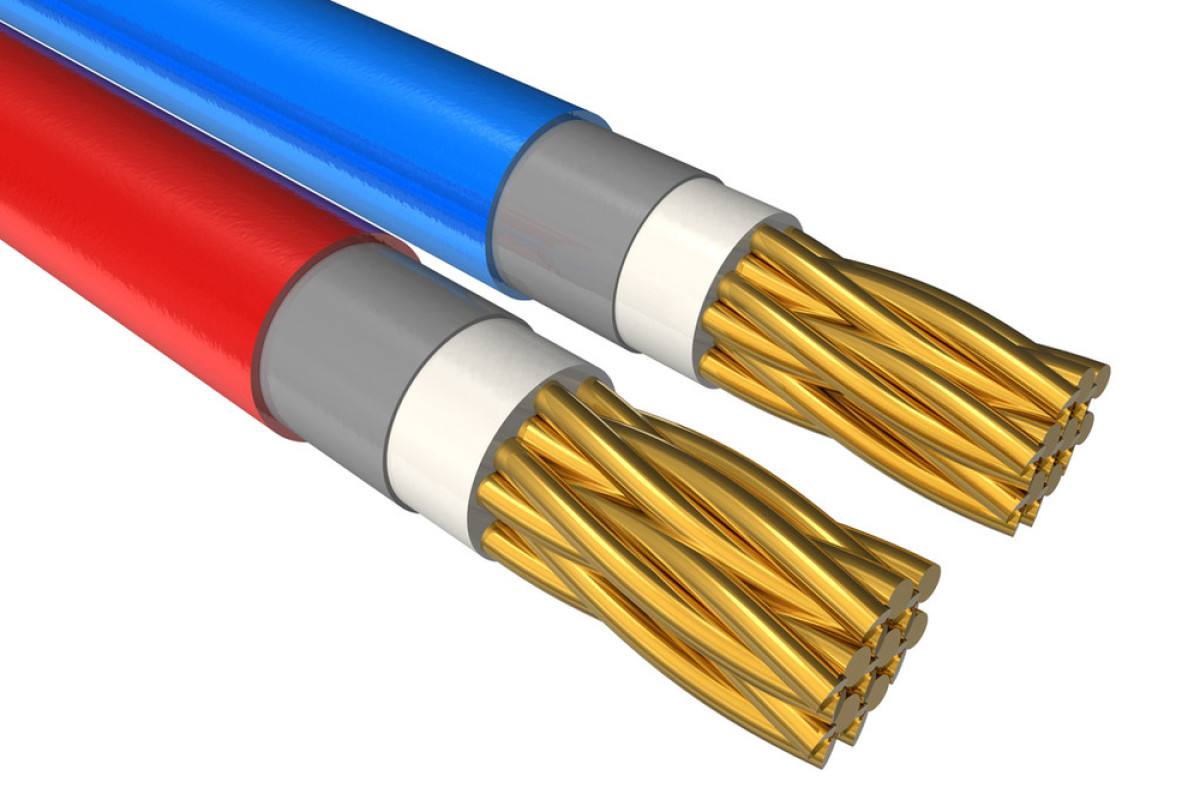

The power system of the power cable is a cable product for transmitting and distributing high-power electric energy in the trunk line.

However, when the power cable passes a certain load current, it will definitely generate heat.

As the load current increases, the cable surface temperature will be higher.

If it is not processed in time, the consequences can be imagined.

For example, a polyvinyl chloride (PVC) cable is considered to have a core temperature of 70 degrees, and the surface temperature is 5 to 10 degrees lower. Therefore, the cable surface temperature is basically safe below 60 degrees.

From the perspective of power supply maintenance, of course, the lower the temperature, the better, so the Asian port talks about the reasons why the power cable is hot during operation.

1 The cable conductor resistance does not meet the requirements, causing the cable to generate heat during operation.

2 The cable selection type is improper, causing the conductor cross section of the cable to be used to be too small, and an overload phenomenon occurs during operation.

After a long time of use, the heat generation and heat dissipation of the cable are unbalanced to cause heat generation.

3 When the cable is installed, the arrangement is too dense, the ventilation and heat dissipation effect is not good, or the cable is too close to other heat sources, which affects the normal heat dissipation of the cable, and may also cause the cable to generate heat during operation.

4 The joint manufacturing technology is not good, the crimping is not tight, and the contact resistance at the joint is too large, which may cause the cable to generate heat.

5 The insulation between the phases of the cable is not good, resulting in a small insulation resistance and heat generation during operation.

6 The partial sheath of the armored cable is damaged.

After the water enters, the insulation performance will be slowly destructive, resulting in a gradual decrease in the insulation resistance, which will also cause heating in the cable operation.

Therefore, after the cable is heated, if the fault is not found, the insulation will break down after continuous continuous energization.

Causes the cable to phase-to-phase short-circuit trip, which may cause a fire. So how do we deal with the problem of heating power cables during operation?

1. The rated voltage of the cable is greater than or equal to the rated voltage of the power supply system at the installation point.

2. The continuous allowable current of the cable should be equal to or greater than the maximum continuous current of the power supply load.

3. The core section must meet the stability requirements of the short circuit of the power supply system.

4. Check whether the voltage drop meets the requirements according to the cable length.

5. The minimum short-circuit current at the end of the line should enable the protection device to operate reliably.

6. High breakdown strength.

7. Low dielectric loss.

8. A fairly high insulation resistance.

9. Excellent discharge resistance.

10. Has a certain degree of softness and mechanical strength.

11. The insulation performance is stable for a long time.