The reasons for the problem with the power cable usually have the following points:

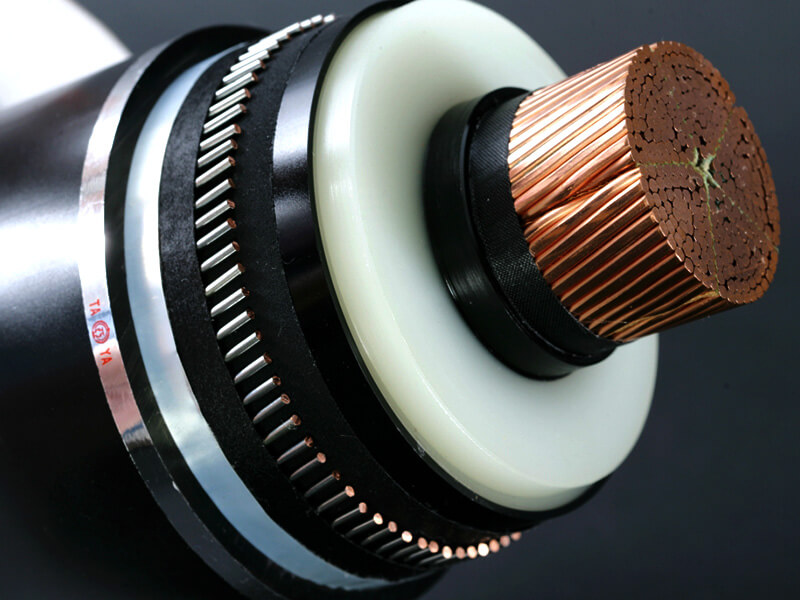

Connecting pipes or terminals are generally important.

Due to the influence of production and storage, there are impurities, burrs or oxide layers.

Especially the aluminum surface is very easy to form a hard and insulating oxide layer.

Only by eliminating these defects, the cable joints and the quality of the process.

The strength of the stripping cable insulation is large, and sometimes it is hard to use a hacksaw.

It is often difficult to damage the conductor.

This damage does not seem serious, but the wire core will be intensified when bent, resulting in a reduction in cross section and increased heat generation.

When the conductor is connected, the length of the insulation stripping is required to be 5 ram deep in the crimping fitting.

Otherwise the gap will be formed at the end of the wire, and the heat will be increased only by the wall thickness.

Some press dies cannot be matched, so the quality of the crimp is not enough.

Some wire and cable connectors are not equipped with lightning rod connectors, which cause lightning strikes in the cable connectors and cause explosions to burn.

Frequently measuring the temperature of the cable joint lead-out point is an effective measure to check the quality of the joint.

Generally, it can be performed by an infrared thermometer.

In summary, the problems in power cables are generally so many.

In general, prevention is the main task.

The quality, innovation and laying work of power cables are strengthened, so that power cables can solve these problems from the root cause.