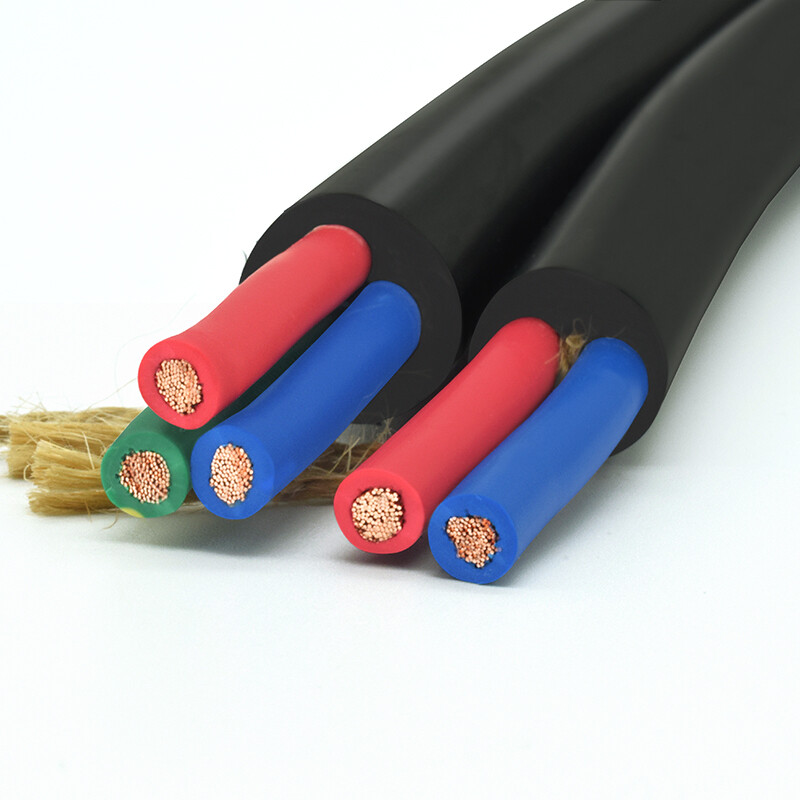

Guide for the implementation of the "gatekeeper" and "prevention first" in the rubber cable test. The content of rubber cable product quality inspection is not limited to the quality inspection of products, but also includes the whole process from raw materials to factory production. The quality inspection and production process of various processes affect the product of a variety of factors, so the scope and content of product quality inspection are wide.

Rubber cable product quality inspection content might include the following:

1. Manufacturing quality inspection parts of the cable materials, auxiliary materials, outsourcing, and product-related rubber.

2. Application of mechanical equipment in rubber cable manufacture.

3. Manufacture of rubber, used for tooling, mold, process equipment inspection.

4. Supervision and inspection of rubber process structure card.

5. Testing of various rubber cables.

6. Rubber cable after the completion of the factory inspection.

7. Production environment test of rubber cable.

8. Manufacture rubber inspection measuring instrument, weighing instrument, instrument, and cable.

There are a lot of product testing methods for rubber cables, which can be divided into the following several methods according to test methods and functions:

1. According to the process: pre-inspection and intermediate inspection.

2. According to the examination of the place: fixed inspection, flow check, or call check.

3. According to the division of labor inspection personnel: their own inspection, that is, self-inspection and full-time inspection.

4. According to the number of tests: general inspection and sampling inspection.

5. There is also a preventive test, which usually refers to the first test and statistical test. The first test is the first activity of quality inspection. The so-called statistical test, is the use of mathematical statistics and probability principles, through a certain number of product testing and analysis to determine the quality of the product and the development trend of the test method.

6. Factory testing includes conventional testing, sample testing, and type testing.