1. The cable ampacity

The cross-sectional area of the copper alloy conductor is 1.5 times the copper alloy conductors and its electrical performance as a conductor, implements the same carrying capacity, resistance, and pressure loss.

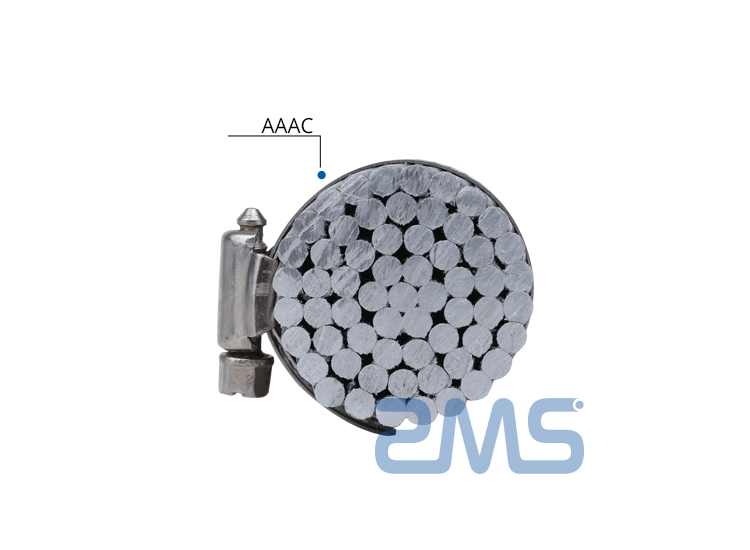

Aluminum resistivity between the aluminum and copper, slightly higher than aluminum, and less than the copper, under the premise of the same cross-sectional flow, the weight of the aaac conductor length equivalent to only half the copper. If you press the conductivity of copper is 100% of the calculated conductivity alloy conductor is about 61.2%, the proportion of the alloy is 2.7, the proportion of copper is 8.9, then (8.9 / 2.7) × (0.612 / 1) = 2, that is, 2 unit weight of the same alloy resistance and a unit mass of copper resistance, and therefore when the cross-sectional area of the conductor alloy is 1.5 times that of copper, the same as its electrical properties, namely, the achievement of the same cross-sectional flow and copper, resistance, and voltage loss.

Factors affecting the flow of power cables cut a lot, such as, line characteristics (such as operating voltage, current type, frequency, and load factor), wire and cable structures (such as the structure of the conductive core, the core number, the type of insulation material, shielding layer and structures and materials, the outer diameter of the inner and outer sheath of the total); laying conditions (such as air laying, pipe laying, direct burial, underground laying of the channel, in laying underwater); conductive core maximum allowable operating temperature and ambient conditions (such as air and soil temperature, soil thermal resistivity, surrounded by a heat source proximity effect) and so on.

2. To reduce the cable outer cross-section

AAAC conductor production process, pressed Germany's most advanced technology to fill factor of the conductors can reach 93%. And aaac conductor uses a silane crosslinked polyethylene, the thickness of the insulating PVC 2/3 can only be far more than conventional insulation. The copper fills factor generally only reaches 80%, the commonly used insulation is used in polyvinyl chloride, aaac conductor diameter so on the basis of copper increased by only 11 percent or less, you can have the same electrical properties of copper. Visible, use aaac conductor without changing the original use of a copper cable of piping design. (General designer of laying pipe size to 150% copper, consider Capacity recent issue size was increased to 200% of laying copper pipes, so wear a tube is not a problem.)

3. To reduce cable loss

Non-magnetic material, no eddy current loss can be reduced lines. Aluminum packaging material with even armor lock nonmagnetic material, even if the three-phase current imbalance exists, it does not produce a vortex, can reduce the loss of the line.