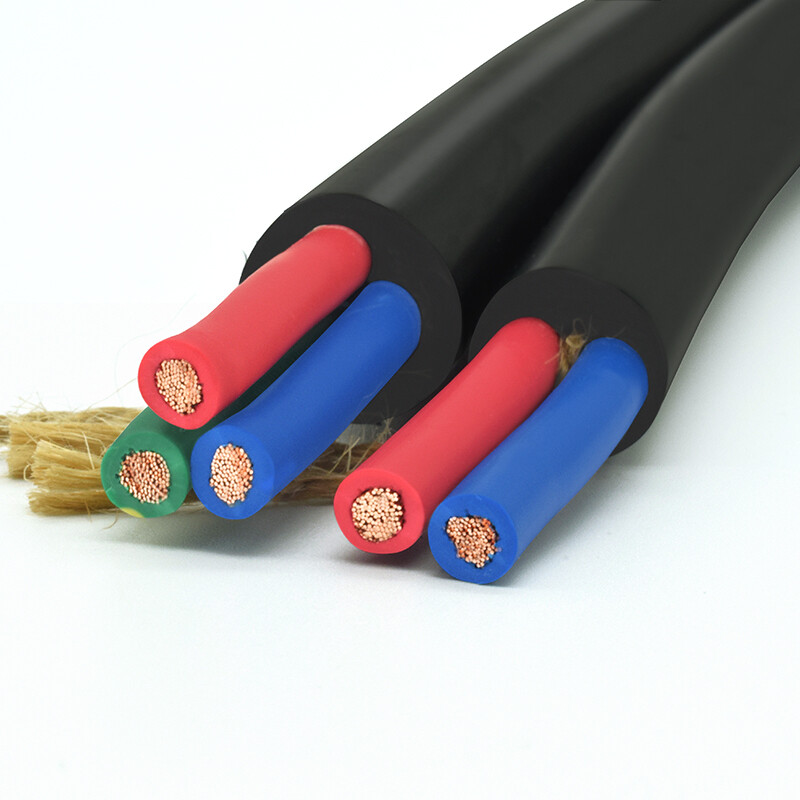

Although the market rubber cable products are different, the craft is the same, is through drawing, and stranding, covered the three kinds of process to produce complete, different types and specifications of the products, the process of making became more and more complex. Here's a simple look at these 3 processes.

1. Drawing

In metal pressure processing. Under the action of external force, the metal is forced through a die (roller), the metallic cross-sectional area is compressed, and access to the required shape and size of the cross-sectional area technical processing method called drawn metal.

Drawing process: wire drawing and stranding drawing.

2. Cutter

In order to improve the flexibility of the rubber cable, the overall degree, so that more than 2 single lines, in accordance with the direction of the call together called the.

Stranding process: conductor stranding, cabling, weaving, and winding steel wire armoring.

3. Coating

According to the different performance requirements of the rubber cable, the use of special equipment in the outer coating of different materials. Coating process:

A. Extrusion package: rubber, plastic, lead, aluminum, and other materials.

B. Longitudinal package: rubber, corrugated aluminum material.

C. Wrapping: a strip of paper tape, mica tape, no alkali glass fiber tape, non-woven fabrics, plastic, etc., line of cotton, silk, and other fiber material.

D. Dip coating: insulation paint, asphalt, etc.