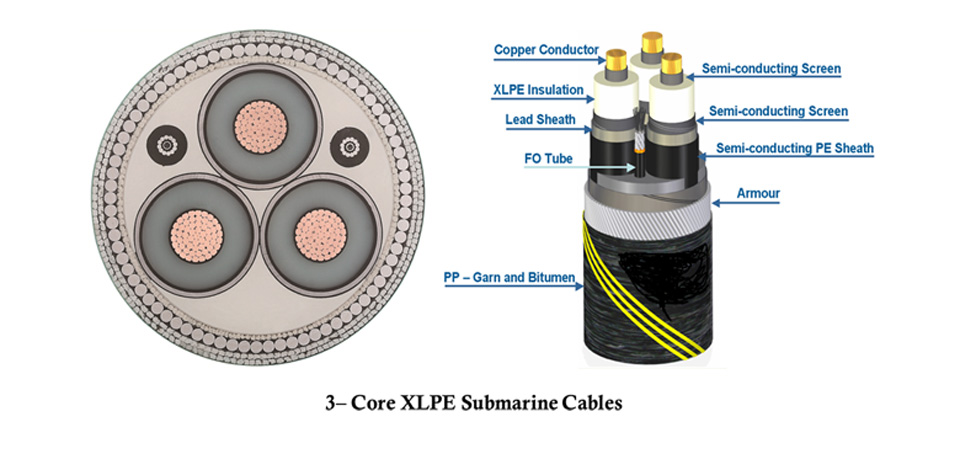

Cross-linked polyethylene insulated (XLPE) submarine cable developed in the last century 80's, most for 220kV and below voltage level [1], its manufacturing and operating experience are far better than oil-filled submarine cable.

Up to now, the highest-voltage XLPE AC submarine cable is the 2.2km long 420kV 4 single-seater submarine cable installed by NEXANS for the large OrmenLange gas field in the Norwegian Sea.

500kV AC long-distance submarine cable, the current application of only oil-filled cable.

① XLPE cable is solid insulation, without the need for a complex oil-filled system, does not need to detect oil level, control oil pressure, and low operating costs.

② XLPE cable without a lead jacket, bending radius is small, lightweight, can be produced, laying longer length, and in the laying of installation and transportation should be more simple than the oil-filled cable.

③ XLPE submarine cable's electrical performance and mechanical properties are also better than oil-filled cable.

Because of this, XLPE insulated submarine cable development has a broader prospect.