A common cable in the hottest sales is armored cable, ZMS produces armored cable, with excellent performance sales to various countries around the world.

In recent years, fiber optic cables are also hot, after the successive development of armored fiber optic cables, we will talk about what is armored fiber optic cables today, it is compared with ordinary fiber optic cables where the special features?

Armored fiber optic cable, as the name suggests, is a kind of external wrapped in a layer of protective "armor" of the cable, its armor is mainly used to protect the fiber optic cable from animal bites, moisture erosion, or other damage.

As the fiber is fragile, the use of optical fiber in various environments must be processed into the corresponding mechanical properties of the optical fiber cable to ensure that the optical fiber in the process of laying, installation, use, and maintenance to ensure that they are not damaged by external forces to ensure that the network is smooth.

Now a large number of outdoor fiber optic cables, and indoor fiber optic cables in complex environments do not give a fundamental guarantee in these properties. Based on this, people developed and designed the armored fiber optic cable.

Armored fiber optic cable has the function of anti-pressure and anti-stretching, can effectively adapt to harsh outdoor environments, and the wiring is much more flexible than pipe wiring. Now, armored fiber optic cable has been widely used in the field of optical communication.

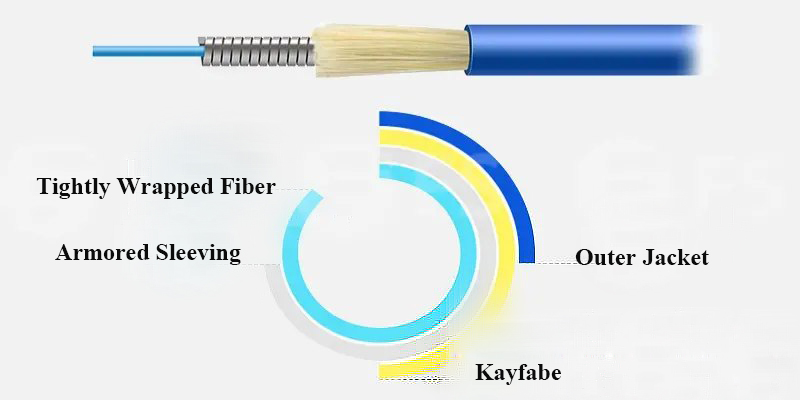

The inner core optical fiber is the part that transmits data signals.

It usually consists of one or more optical fibers, each of which consists of a core and cladding. The kernel fiber is used to transmit optical signals from one end to the other.

The filler sits between the core fiber and the metal armor, filling in the gaps and providing protection and support. It can be a loose polymer material or a gel-like substance encased around the fiber.

In the design of armored fiber optic cables, the outer jacket protects the cable from solvents and abrasion and is usually made of plastic, such as polyethylene.

Between the outer jacket and the inner jacket is the armoring, which is a material that is difficult to cut, chew and burn, and also prevents the cable from stretching during laying.

As shown in the figure below, the 12-core armored fiber optic cable contains 12 optical fibers and two layers of inner and outer jackets, with the metal armor located between the inner and outer jackets, and a layer of aramid yarn between the outer jacket and the metal armor:

It is a protective and flame-retardant material that supports the inner fiber optic cable bundle. In simple terms, in an armored fiber optic cable, the buffer conduit surrounds a layer of aramid yarn, a polyethylene jacket, and corrugated steel armor.

Armored fiber optic cables can be divided into indoor armored fiber optic cables and outdoor armored fiber optic cables according to the application of the fiber optic cable.

Indoor armored fiber optic cable includes single-layer armored and double-layer armored fiber optic cable. Double-armored fiber optic cables are used in shallow coastal waters, while single-armored cables are used in situations other than these extreme conditions.

Outdoor armored fiber optic cables can be divided into light armored cables and heavy armored cables. Typically heavy-duty armored cables are used under rivers and the sea, so light-duty armored cables are less expensive than heavy-duty armored cables.

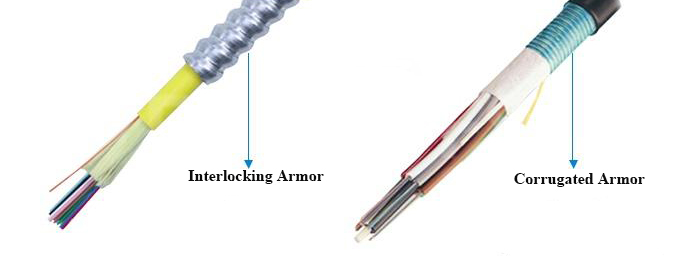

In addition, armored fiber optic cables can also be divided into interlocking armored fiber optic cables and corrugated armored fiber optic cables according to the different types of metal armor.

Interlocking armored fiber optic cables are spooled with aluminum armor and are commonly used in both indoor and outdoor environments with high durability and high compression resistance.

Corrugated armor is a longitudinal fold of steel tape wrapped around the fiber optic cable and is commonly used in outdoor environments to provide superior mechanical properties and protection against rodent bites.

According to the different laying environments, armored fiber optic cable can be divided into tightly armored fiber optic cable and loosely armored fiber optic cable.

Loose armored cables are usually used in outdoor applications; tightly armored cables can be used in indoor applications and indoor/outdoor applications.

Indoor/outdoor armored fiber optic cables are widely used in modern telecommunication networks as a link between two or more building networks.

Outdoor armored fiber optic cables use corrugated armor, which is high tensile, high compression, and anti-rodent bite.

Outdoor fiber optic cables are also introduced in the type of overhead fiber optic cables. Aerial cables serve numerous purposes in our daily lives. Fiber optic cables in the form of overhead are also easier to manage and safer.

If it is an outdoor aerial fiber optic cable, to avoid harsh environments, people or animal damage (such as the frequent occurrence of people with birdshot birds when the optical fiber breaks), play a role in protecting the fiber core, generally armored fiber optic cable. Recommended light armor with steel armor, cheap and durable to be better.

The use of light armor, but the price is cheap and durable.

General outdoor aerial fiber optic cable has two kinds: one is the center of the beam tube type, and the other is a layer of stranded type.

For the sake of durability, aerial mostly uses one layer of the sheath, while direct burial uses two layers of the sheath to be safer.

In the field of modern fiber-optic communications, any fiber failure may cause significant financial and material losses, so the protection of optical fiber in a fiber-optic communication system installation process is the most important.

The optical fiber is wrapped on the outside of a layer of protective "armor" armored fiber optic cable to meet the requirements of people anti-rodent bite, moisture, anti-stretch, and so on.