This building cable, as defined by the National Electrical Code, is for usage in construction. Engineers also commonly use THHN in machine tools, control circuits and some appliances.

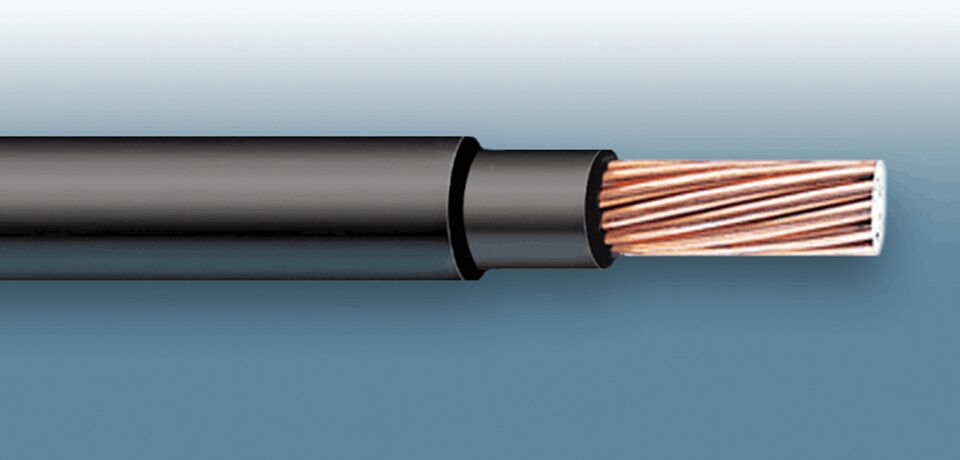

THHN cable comes in a variety of types. The cable comes in two types of conductors depending on the size: stranded or solid. It’s manufactured with either copper or aluminum, and it’s covered in a polyvinyl chloride (PVC) insulation with a nylon jacket.

Aside from the mechanical protection, a nylon jacket protects the cable from abrasion as it’s pulled through conduit. In addition, such jacketed cable is protected from hydrocarbons such as oil, gasoline and grease. Cut-through protection is also increased with nylon jackets while protecting the insulation.

The use of nylon jackets also enables a reduction in the amount of insulation required, allowing a conduit to contain more low voltage cables compared to non-jacketed cables of the same current carrying capacity. This can be especially advantageous when utilizing built-in or underfloor systems.

The cable is approved for up to 600 volts and is listed by Underwriters Laboratory (UL), an independent product standards company, as rated for 90 degrees Celsius in dry locations and 75 degrees Celsius in wet environments. Much of THHN low voltage cable comes with a dual rating: THHN/THWN, which means it’s appropriate for both wet and dry applications.

Easy to wear tube. Fine cable diameter, wear coefficient significantly reduced wear.

Increased cable conduit threading capacity. cable diameter is small, for the same size of the catheter can penetrate the cable or a large flow.

Excellent wear resistance to reduce damage to the insulation when the cable through the pipe and laying. This is very important, which can effectively reduce the hidden dangers of short-circuit accidents.

Excellent resistance to hydrocarbons, chemical stability, that is, excellent oil, gas and gas corrosion resistance of the gas, effectively improve the reliability and service life of the cable (aging test proved THHN type cable Than the original PVC-type cable life of at least 40 years or more).

High safety performance. The tested THHN cable has good thermal stability and thermal shrinkage. This will help to avoid the possibility of over-heating of the grounding point to cause the insulation of the cable to shrink and expose the copper cable to cause short-circuit fault.

Has the ability to withstand considerable short-circuit current, short-circuit withstand temperature of 5 seconds to be higher than ordinary PVC type. This is because of the nylon jacket, which has a melting point of 215 ° C.

With the same flame retardant PVC insulation properties. According to the experts test, the toxicity of combustion is far less than the release of PE.

Manufacturer's name, product model, voltage level and other signs printed on the PVC insulation and nylon sheath between the logo is clear, scratch-resistant.