DIN VDE 0276 is the widely used German standard for cables with extruded insulation used in power distribution systems. This standard covers a significant percentage of power cables used across the European continent. It covers the various cable construction and test methods, and it consists of the following parts:

DIN VDE 0276

Part 1: General requirements

Part 10-C: Construction, dimensions, and test requirements of single-core power cables with XLPE-insulation and with PE-sheath or PVC-sheath for rated voltage of 6/10 kV, 12/20 kV, and 18/30 kV and of three-core power cables with XLPE-insulation and with PE-sheath or PVC-sheath for rated voltage of 6/10 kV for fixed installations

Part 603: Distribution cables of nominal voltages 0.6/1kV

Part 604: Power cables of nominal voltages 0.6/1kV with special fire performance for use in power stations

Part 604 & 605: Additional test methods

Part 620: Distribution cables of nominal voltages 3.6 to 20.8/36kV

Part 1000: Current carrying capacity, general, conversion factors

Part 1001: Tests on cables laid with nominal voltages of 6/10kV,12/20kV, and 18/30kV with PVC insulation, VPE insulation, or paper insulation

Range of cables manufactured to VDE 0276

A wide range of cables can be manufactured in accordance with VDE 0276. A number of these cables are always available from stock or in production and are generally available for same-day despatch. This includes copper conductor cables N2XCH and N2XH cable, N2XS2Y cable, N2XSEY cable, N2XSY cable, and the aluminum conductor equivalents NA2XS2Y cable, NA2XSY cable, NA2XY cable, and NAYY cable & NYCY cables.

These cables are suitable for permanent laying in dry and wet spaces over, on, in, and under plaster. Cables manufactured in accordance with VDE 0276 can be laid in pipes/cables ducts, directly in-ground, or in free air.

The specifications of N2XSY XLPE PVC - 12/20 (24)kV Cable

Application:

Medium voltage cables for distribution networks; also for connection to generation units and plant and process connection. To be laid directly on the ground, outdoors, indoors, and in cable ducts.

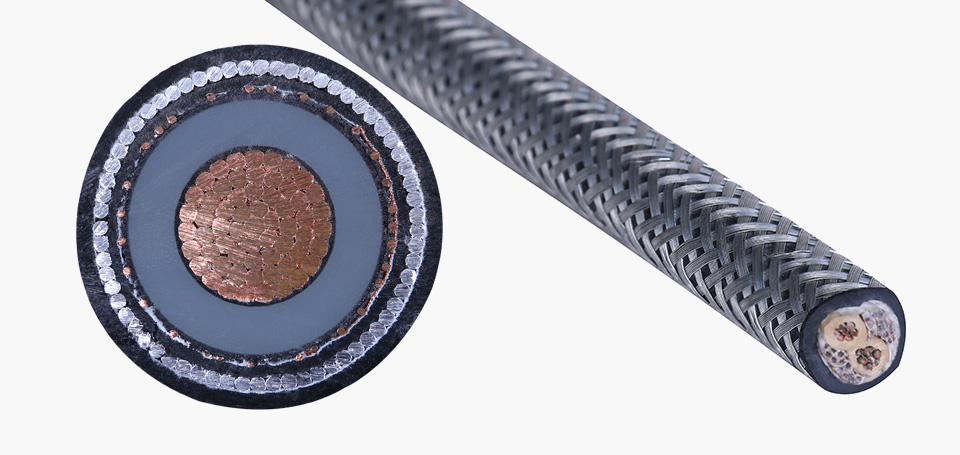

Construction:

Conductor: Stranded copper

Conductor Inner Semi-Conductive Layer: Semi-conductive material

Insulation: XLPE (Cross-Linked Polyethylene)

Outer Semi-Conductive Layer: Semi-conductive material

Screen: Copper wires

Sheath: PVC (Polyvinyl Chloride)

Cable Standard: DIN VDE 0276-620, HD 620 S1, DIN/BS EN 60228, BS EN/IEC 60332-1-2

Characteristics:

Voltage Rating: (Uo/U)(Um) 12/20 (24)kV

Test Voltage 42kV

Temperature Rating Fixed: -20°C to +70°C Flexed: -5°C to +70°C

Short Circuit Temperature: +250°C

Minimum Bending Radius: 15 x overall diameter

Sheath Color: Red

The specifications of NA2XS2Y Aluminium Conductor XLPE PE - 6/10 (12)kV Cable

Application:

Medium voltage cables for distribution networks; also for connection to generation units and plant and process connection. To be laid directly on the ground, outdoors, indoors, and in cable ducts.

Construction:

Conductor Class 2 stranded aluminum conductor Inner Semi-Conductive Layer Semi-conductive material Insulation XLPE (Cross-Linked Polyethylene) Outer Semi-Conductive Layer Semi-conductive material Screen Copper wires Sheath PE (Polyethylene)

Cable standard:

DIN VDE 0276-620, HD 620 S1, DIN EN 60228, BS EN/IEC 60332-1-2

Characteristics:

Voltage Rating (Uo/U)(Um) 6/10 (12)kV

Test Voltage 21kV

Temperature Rating Fixed: -20°C to +70°C Flexed: -20°C to +70°C

Short Circuit Temperature +250°C

Minimum Bending Radius 15 x overall diameter

Sheath Colour Black