Solar energy technology will become one of the future green energy technologies.

Solar energy or photovoltaic (PV) applications are becoming increasingly widespread in China.

In addition to the rapid development of government-supported photovoltaic power plants, private investors are also actively building plants and are planning to start production worldwide of solar modules.

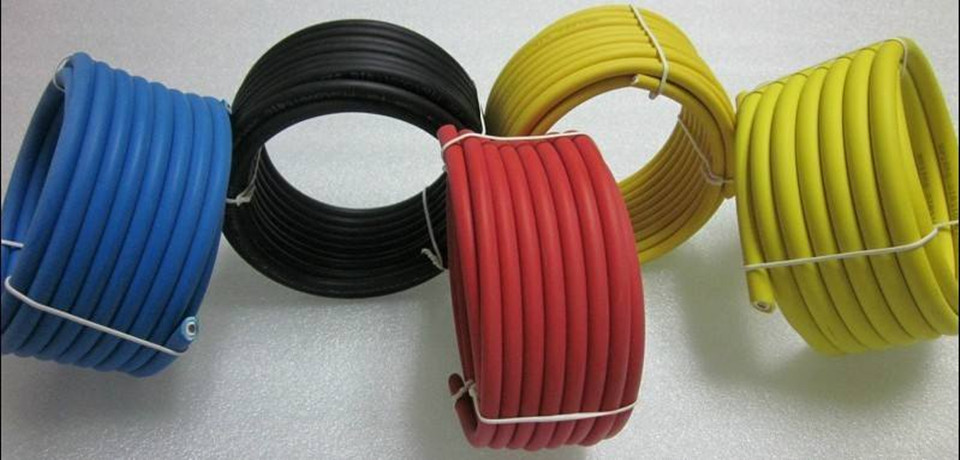

STRUCTURE:

1.Tinned Copper wires conductor

2.XLPO insulation

3.XLPO outer sheath

The characteristics of photovoltaic cables are determined by their special insulating materials and sheathing materials for cables.

We call them cross-linked PEs.

After irradiation accelerator irradiation, the molecular structure of the cable material will change to provide its performance in every aspect.

Anti-mechanical load In fact, during installation and maintenance, the cable can be routed on the sharp edges of the roof structure while the cable is subjected to pressure, bending, tension, cross tensile load and strong impact.

If the strength of the cable jacket is not sufficient, the cable insulation will be severely damaged, which will affect the service life of the entire cable or cause short circuit, fire and danger of personal injury.

In the solar photovoltaic power generation system, the cables used in the low-voltage direct current transmission part have different requirements for the connection of different parts because of different use environments and technical requirements.

The overall considerations are: insulation performance of cables, heat-resistant and flame-retardant performance, Engage in aging performance and wire diameter specifications

Photovoltaic special cable: PV1-F1*4mm2

The cables used to connect the cables to the combiner box are generally used:

PV-specific cables PV1-F1*6mm2

Characteristics: The photovoltaic cable has a simple structure.

Its polyolefin insulation material has excellent heat resistance, cold resistance, oil resistance and ultraviolet resistance.

It can be used under harsh environmental conditions and has a certain mechanical strength.

Laying: It can be protected by wearing the pipe, using the component bracket as the passage and fixing of the cable laying, reducing the influence of environmental factors.