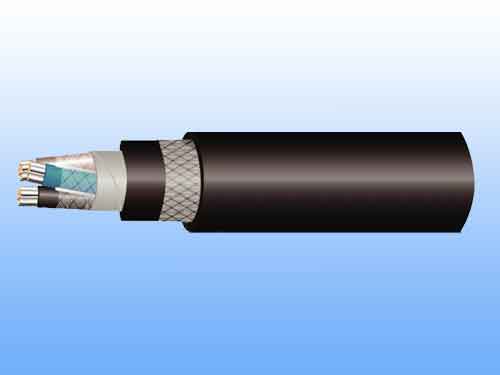

The basic structure of the cable is mainly composed of three parts:

The conductive core is used to transmit electrical energy.

The insulating layer ensures the transmission of electrical energy along the core, and the core is electrically isolated from the outside.

The protective layer acts as a protective seal to prevent the insulation from being immersed in moisture.

It is protected from external damage and maintains insulation properties.

Power cables are generally manufactured at a certain voltage level, and the voltage levels are 0.5kV, 1, 3, 6, 10, 20, 35, 60, 110, 220, 330kV. Among them, the 1kV voltage class power cable is the most used.

Power cables with voltage levels of 3 to 35 kV are often used in major power lines in large and medium-sized buildings.

Power cables of 60 to 330kV voltage class are used in power transmission lines where overhead conductors are not suitable, and installations such as crossing rivers and seabeds.

According to the voltage coarse division, it can be divided into low voltage cable less than 1kV and high voltage cable greater than 1kV.

From the aspects of construction technical requirements, cable joints, cable termination structure and operation and maintenance.

It is also divided into low-voltage power cables, medium-voltage power cables (1 to 10kV), and high-voltage power cables.

The conductive core wire of the power cable is manufactured according to a certain level of nominal cross-sectional area, which is convenient for manufacturing, design and construction selection.

The nominal cross-sectional area of power cables in China is 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240, 300, 400, 500, 600 mm2, a total of 19 kinds. The high-voltage oil-filled cable has a nominal cross-sectional area of 6 types of 100, 240, 400, 600, 700, and 845 mm2.

Multi-core cables are based on the phase line with the largest cross section.

The conductive cable of the power cable has 5 to 5 cores.

Single-core cable for single-phase AC, DC and special applications (high-voltage motor lead-out). Oil-filled and gas-filled high-voltage cables with voltage levels of 60kV and above are mostly single-core.

Two-core cables are mostly used to transmit single-phase AC or DC power.

The three-core cable is used in three-phase AC power grids and is widely used in cable lines up to 35kV.

The four-core cable is used for low-voltage distribution lines, neutral point grounding TT mode and TN-C mode power supply system.

The five-core cable is used for the TN-S mode power supply system with low-voltage distribution lines and neutral grounding.

Both the core and the four cores are cables with a low voltage of 1 kV or less.

Oil-impregnated paper insulated power cable: It is the oldest, most widely used and most commonly used cable with low cost, long life, heat resistance and stable electrical resistance.

Widely used in a variety of low voltage power cables.

It is usually made of paper as the main insulation and fully impregnated with an insulating impregnating agent.

According to the conditions of the impregnating agent and the insulation structure, it is divided into the following types. Ordinary viscous impregnated paper insulated cable, the impregnating agent is a viscous impregnating agent which is a mixture of low-pressure cable oil and rosin.

According to the structure, it is divided into turn-on type, split-phase lead (aluminum) package type and split-phase shielding type.

Plastic insulated cable: plastic insulated cable is simple to manufacture, light in weight, easy to manufacture in the terminal and middle head, small in bending radius, simple in laying, easy to maintain, resistant to chemical corrosion and water, and used in high drop and vertical laying applications.

Plastic insulated cables are PVC insulated cables and XLPE insulated cables.

The former is used in cable lines below 1kv, and the latter is used in lines above 10kV to high voltage cables.

Rubber insulated cable: Because rubber is elastic, stable performance, good electrical, mechanical and chemical properties, it is widely used in cables below 1kV. Flame-retardant PVC insulated cable: The common disadvantage of the first three cables is that the material is flammable.

When an accident occurs in the line or at the joint, the cable may burn due to local overheating, expanding the scope of the accident.

The flame-retardant cable is made by adding a flame retardant to the polyvinyl chloride, and it will not burn even if it is on an open flame.

It is a kind of plastic cable used in cable lines below 10kV.

The design safety factor of insulated conductors and strands of insulated conductors shall not be less than 3.

The self-weight load of the steel strands with insulated wires shall include the insulation wire, steel strand, insulation bracket quality and 200kg construction load.

The minimum cross section of the strand should not be less than 50mm2.

Wires of different metals, different specifications, different twisted wires and bundle wires without bearing wires are strictly prohibited from connecting within the gear distance.

Within one gear, each conductor should not exceed one load-bearing joint.

The fixing point of the joint from the wire shall not be less than 500mm.

The safety factor of the insulating bracket shall not be less than 5, and the breaking tensile force of the insulating rod shall not be less than 90% of the calculated breaking force of the wire.

And the breaking stress of the insulating bracket and the insulating rod should meet the requirements of the maximum short-circuit electric power.