Classification

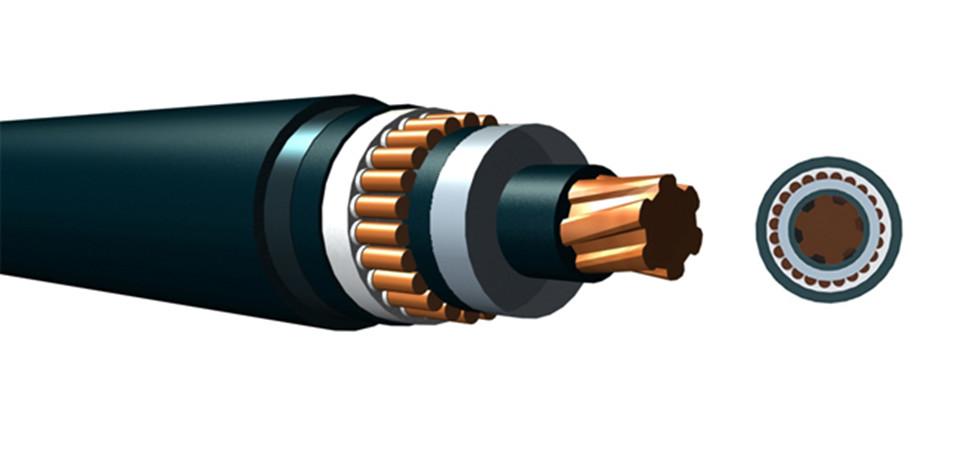

The armor is divided into steel belt armor (22, 23), thin steel wire armor (32, 33), and thick steel wire armor (42, 43).

Steel cable armored cable models are VV22, VVP22, ZRVV22, and NH-VV2.

Control cable steel cable armored cable, models are KVV22, KVVP2, KVVP22, ZR-KVV22.

The steel wire armored power cable and cable, models are VV32, YJV32, and ZR-VV32.

Wire armored control cable Model KVV32 KVVP32.

Armored communication cable models: HYA53, HYAT53, HYA23, HYV22, HYA22 (anti-rat, buried)

The production of foreign armored cables is mainly concentrated in several developed countries, such as the United States, the United Kingdom, Japan, Germany, and Russia, and there are no manufacturers in Southeast Asia, but as long as there are chemical, metallurgical, mechanical manufacturing, power generation and other industries With temperature measurement, an armored cable is required.

Use

The armored cable mechanical protective layer can be added to any structural cable to increase the mechanical strength of the cable and improve corrosion resistance.

It is a telephone cable designed for areas that are susceptible to mechanical damage and extreme erosion. It can be laid in any way and is more suitable for direct burial in rock areas.

The armored cable is generally a fixedly laid power cable. Generally speaking, it is fixed in one place and basically does not move, and the power line transmits electric energy.

In addition to the above, the purpose of the cable plus the armor layer can also enhance mechanical protection such as tensile strength and compressive strength to prolong the service life.

The armor has certain anti-external force performance, and can also prevent rats from biting. It will not cause power transmission problems through armoring.

The bending radius of the armor should be large, and the armor layer can be grounded to protect the cable.