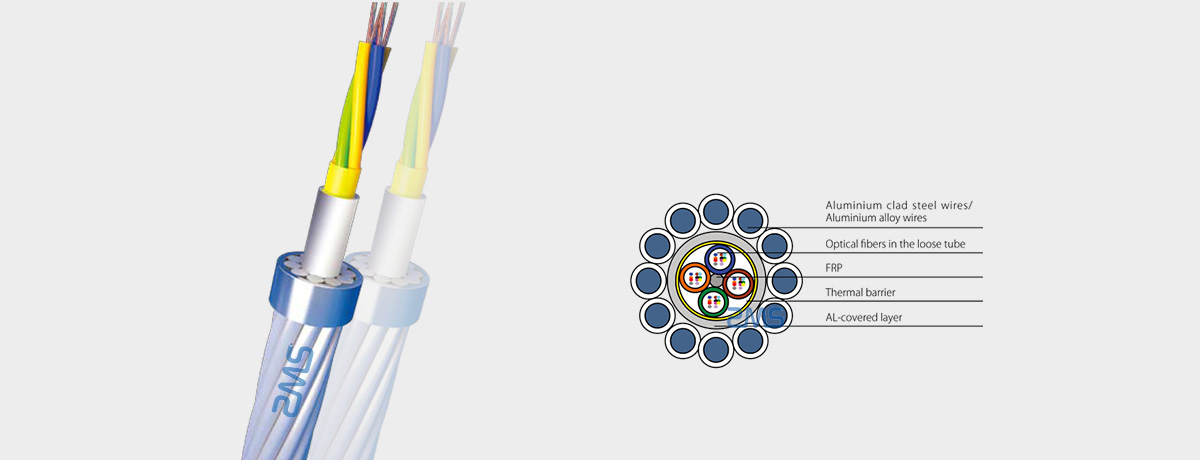

Optical fiber composite overhead cable ground wire (OPGW), also known as fiber optic overhead cable ground wire, optical fiber unit is used for communication in the power transmission lines for the ground contains. As a power system dedicated to special cable, high strength, stable performance, no electric corrosion, etc.,

It has two functions, one is a lightning-line transmission lines transmission line to provide shielding for protection against lightning discharges; secondly, the composite fiber in the ground as a medium to transmit optical signals can transmit audio, video, data, and various control signals, the formation of the multi-way broadband communications network. Currently, in power systems, optical fiber communication backbone network is widely used.

However, because of the high voltage lines with poles, and cater to the ground, therefore, it has become an important factor affecting the performance of OPGW safety, how to improve OPGW anti-lightning performance has become one of the most serious challenges facing OPGW.

There are two methods commonly used in the operation, first, to improve the shape of the strands and the cable structure, mainly in the inner layer between the outer strands and the strands leave the air gap, to prevent heat conduction to the inner layer and the outer layer of the fiber, in order to protect the inner fiber. Second, in lightning-prone areas adjust the ratio of the outer strands materials to improve the outer filaments level of anti-lightning.

But there is a flaw in this way, due to the increase of timber, the weight of the cable itself increases, resulting in pressure on the tower weighing, increasing the difficulty of construction, and also increasing production costs.