High voltage grounding lines, also known as grounding conductors or grounding cables, play a crucial role in electrical engineering and infrastructure development.

These essential components provide a pathway for fault currents to safely dissipate into the ground, thereby preventing electrical shocks, equipment damage, and catastrophic failures.

In this comprehensive guide, ZMS Cable delves into the significance of high voltage grounding lines, exploring their function, design considerations, installation practices, and maintenance strategies.

High voltage grounding lines serve as a vital safety mechanism in electrical systems, especially those operating at elevated voltages.

When faults occur, such as short circuits or insulation failures, excessive currents can flow through conductive components, posing serious risks to personnel and equipment.

Grounding lines provide a low-impedance path for these fault currents to flow into the earth, effectively diverting them away from sensitive equipment and personnel.

One of the primary functions of high voltage grounding lines is to protect personnel from the hazards of electric shock.

By providing a direct path to ground for fault currents, these grounding conductors help to limit the potential difference between conductive surfaces, reducing the risk of electric shock to individuals working close to electrical equipment.

In addition to safeguarding personnel, high voltage grounding lines also protect electrical equipment from damage caused by excessive fault currents.

By promptly diverting fault currents away from sensitive components, grounding conductors help to minimize the risk of equipment overheating, insulation breakdown, and mechanical stress, thereby extending the lifespan of electrical assets.

High voltage grounding lines play a crucial role in maintaining the stability and reliability of electrical systems.

By providing a low-impedance path for fault currents, these grounding conductors help to mitigate voltage fluctuations, transient overvoltages, and electromagnetic interference, thereby ensuring uninterrupted operation of critical infrastructure and minimizing the risk of system failures.

Designing effective high voltage grounding lines requires careful consideration of various factors, including:

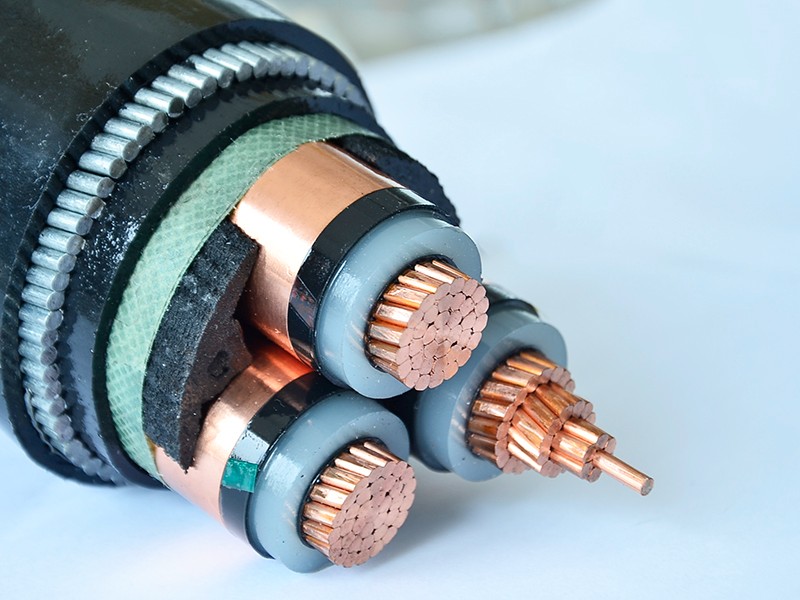

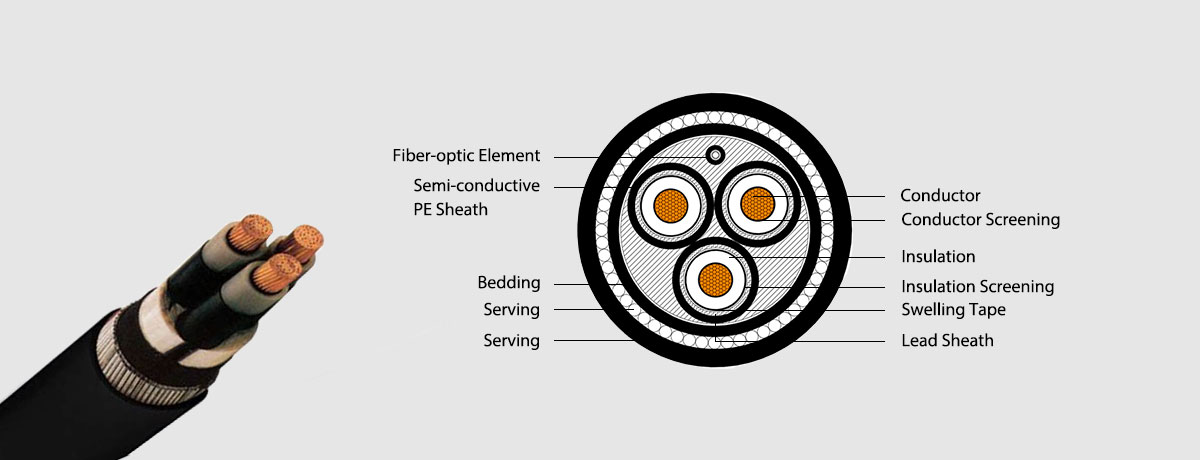

The size and material of the grounding conductor significantly influence its ability to carry fault currents safely. Typically, high-conductivity materials such as copper or aluminum are preferred for grounding conductors, and the conductor size is selected based on the magnitude of fault currents expected in the system.

The effectiveness of a grounding system depends on the type and condition of the grounding electrodes used. Common grounding electrodes include ground rods, ground plates, and grounding grids, each offering different levels of resistance to earth and suitability for specific soil conditions.

High voltage grounding lines should be installed near electrical equipment and connected to the equipment's grounding terminals using robust and secure connections.

The routing of grounding conductors should follow the shortest and most direct path to the ground, avoiding sharp bends, obstructions, and proximity to other conductive materials.

In areas prone to lightning strikes or transient overvoltages, additional surge protection devices such as lightning arrestors or surge suppressors may be installed in conjunction with high voltage grounding lines to further enhance system protection and reliability.

Proper installation of high voltage grounding lines is essential to ensure their effectiveness and reliability. Key installation practices include:

Before installing grounding conductors, conducting a site survey and soil testing can help identify potential hazards, soil resistivity levels, and optimal locations for grounding electrodes, ensuring the effectiveness of the grounding system.

Grounding conductors should be installed using approved methods and techniques to ensure secure connections, adequate bonding, and compliance with relevant safety standards and regulations.

Proper bonding materials, such as exothermic welding compounds or mechanical connectors, should be used to establish reliable connections between grounding conductors, electrodes, and electrical equipment, minimizing resistance and ensuring low-impedance fault current paths.

Periodic inspections and maintenance activities are essential to ensure the ongoing integrity and effectiveness of high voltage grounding lines.

Inspections may include visual assessments, resistance measurements, and soil testing to identify any signs of corrosion, damage, or degradation that could compromise the grounding system's performance.

In conclusion, high voltage grounding lines play a critical role in ensuring the safety, reliability, and stability of electrical systems operating at elevated voltages.

By providing a low-impedance path for fault currents to dissipate into the earth, these essential components help to protect personnel, prevent equipment damage, and maintain system integrity.

Proper design, installation, and maintenance of high voltage grounding lines are essential to ensure their effectiveness and reliability in safeguarding electrical infrastructure against the risks of electrical faults and transient events.

As technology continues to evolve and electrical systems become increasingly complex, the importance of high voltage grounding lines in promoting safety and reliability remains paramount, driving innovation and best practices in electrical engineering and infrastructure development.