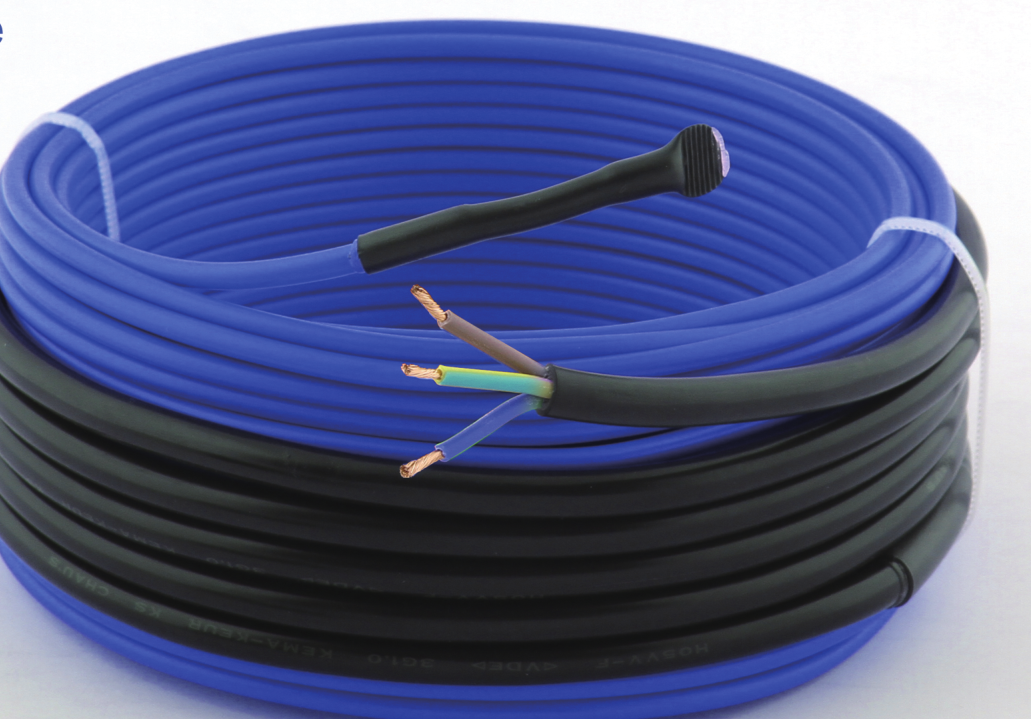

Mineral insulated heating cable is made of single or multiple alloy heating wires as a heat source, high purity, high temperature, fused crystalline magnesium oxide as a thermal insulator, seamless continuous stainless steel or brass as a sheath, made of special production process The Corrosion-resistant places can be added PE or deferred halogen-free jacket.

Mineral insulation heating cable mechanical properties, because of its strong structure, can be resistant to twisting, extrusion, bending, pulling, and friction.

And general heavy handling; the product insulation layer of magnesium oxide is an inorganic material, and the core and outer jacket Are made of metal which fundamentally solves the aging problem, greatly extending the service life of the cable.

Mineral insulated heating cables should pay attention to the following when installation:

1 In the cable laying up and down two layers, should be used pure cement, should not be mixed with stones to avoid damage to the cable.

2 According to the size of the road load, the upper and lower layers of cement thickness should be a corresponding change.

3 To avoid snow cable directly connected to the power supply, should be through the cold side of the cable.