(1) When the new whole cable is shipped from the factory, both ends are sealed with plastic sealing sleeves.

However, after the construction site is used according to the actual situation, the remaining part is wrapped with plastic cloth to break the gap.

It is placed in the open air and the seal is not good. For a long time, it will inevitably have water vapor infiltrated into the cable.

(2)When laying cables, it is necessary to frequently cross roads, bridges, and culverts.

Due to weather or other reasons, water is often accumulated in the cable trenches.

In the process of laying, it is inevitable that the cable heads will be immersed in water.

Because the plastic cloth is not tightly wrapped or damaged, the water enters the cable.

In addition, when the traction and the pipe are worn, the outer sheath or even the steel shovel is sometimes scratched. This phenomenon is particularly prominent when using mechanical traction.

(3) After the cable laying is completed, the cable head is not produced in time due to the limitation of on-site construction conditions, so the unsealed cable breakage is exposed to the air for a long time, even immersed in water, so that the water vapor enters the cable in large quantities.

(4) During the manufacture of the cable head, due to the negligence of the construction personnel, the newly processed cable ends may accidentally fall into the accumulated water at the site.

(5)In the normal operation of the cable, if a breakdown such a breakdown occurs for some reason, the water in the cable trench will enter the cable inside the fault point.

In civil construction, especially when using large construction machinery It is not uncommon for a construction site to have cable breakage or breakdown due to various human factors.

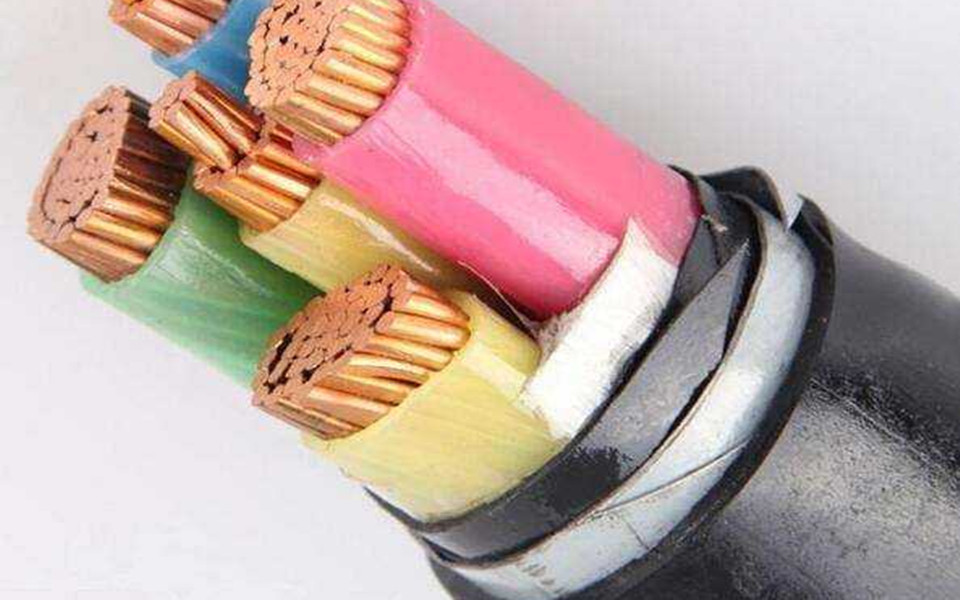

(1)At present, we have adopted a cable of 8.7/10kV grade in the urban network 6kV system transformation.

The insulation thickness of this grade cable is 4.5mm, and the insulation thickness of the 6/10 kV grade cable is 3.4mm.

Due to the increase in the insulation thickness of the cable, the field strength is reduced, and the aging of the water tree can be prevented.

At the same time, since the 6kV neutral point small current grounding system is grounded in a single phase, the cable is subjected to a phase voltage of 1.73 times and is required.

It takes 2 hours to run, so it is necessary to thicken the cable insulation.

(2)Since impurities, pores, etc. in the insulation are the starting point of water tree generation, the quality of the cable is essential to prevent water tree aging.

When purchasing cables, we must choose manufacturers with high quality.

We must carry out rigorous tests on the samples sent by each manufacturer, and require all manufacturers to bid, and choose high-quality and low-priced products.

(3)Ensure that the cable head is well sealed.

For the cable ends that are sawed, whether it is stacked or laid, they should be sealed with plastic. It is best to use a special sealing sleeve for the cable to prevent moisture infiltration.

(4)After the wire is laid, it is necessary to make the cable head in time. If it is impossible to make it immediately due to conditional restrictions, the cable head is sealed and placed in an overhead position.

(5)Improve the technical quality of construction workers and strengthen the management of the cable head manufacturing process, which can effectively prevent the cable head from entering the water during the production process. The practice has proved that once the cable enters the water, the earliest breakdown phenomenon is often the cable head, so the wire head is made well and can extend the overall life of the cable.

If the cable is peeling off the semiconductor layer, we first circumscribe the specified size on the semiconductor layer, then draw a few vertical lines, and then strip the semiconductor along the strip.

When using a knife, the strength must be properly controlled.

If it is too shallow, the semiconductor layer is difficult to remove. If it is too deep, it will damage the insulation layer and bring opportunities to the water tree.

In the case of a cable that cannot be stripped by a semiconductor, the semi-conductive layer must be scraped off with a glass piece.

This requires the construction personnel to be careful and careful. It is necessary to clean the semi-conductive layer and avoid damage to the main insulation. Smooth the main insulation surface.

(6)When the cable is directly buried, we use PPR's new plastic pipe as the casing.

The pipe is corrosion-resistant, the inner wall is smooth, and the strength and toughness are good, so the damage to the cable's outer sheath can be greatly reduced.

Due to the limitation of conditions, the local cable laying is in the form of direct burial or cable trench.

It is located in a coastal area.

The local area is mostly saline-alkali land. In addition, the drainage is not smooth, resulting in water accumulation in the cable trench or cable well.

Therefore, in the early planning, the design of cable trenches, culverts, and cable wells should be coordinated with the civil construction party in time to facilitate the drainage of cable trenches (wells).

At the same time, the bracket is pre-buried in the cable trench, and the cable is supported by the bracket.