Power cable is the most extensive, the most in-demand cable product in the power transmission, distribution, and other essential electrical transfer line.

With social progress and economic development, humans depend on electrical energy more and more, and the demand for electrical energy is increasing.

However, most countries in the world have a problem of uneven distribution of energy and productivity.

Therefore, building large-capacity and long-distance power grids has drawn great attention from governments of all countries.

To reduce line loss in long-distance transmission, high-voltage transmission technology is required.

China is actively developing EHV and UHV transmission and distribution lines.

Along with the development of EHV transmission technologies, more and more high demands are placed on power cables, which are an essential component of the power grid and must withstand high voltage and ultrahigh voltage.

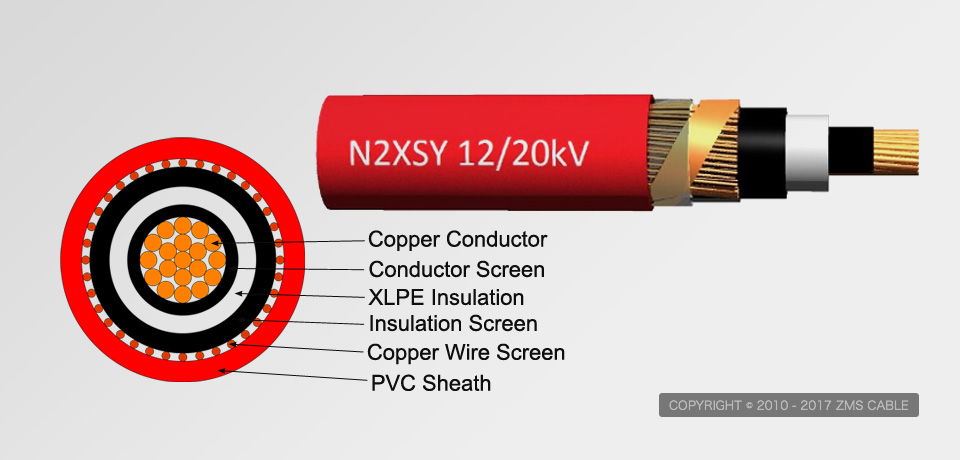

A cable is usually a rope-like cable made up of several wires or groups of wires, each group of at least two twisted together.

Each group of wires is insulated from each other and often twisted around a center, and the entire outer covering is covered with a highly insulating covering.

Cables have the characteristics of being energized internally and insulated externally.

Cables are power cables, control cables, compensation cables, shielded cables, high-temperature cables, computer cables, signal cables, coaxial cables, fire-resistant cables, marine cables, mining cables, aluminum alloy cables, and so on.

They are all made up of single or multi-stranded wires and insulation and are used to connect circuits, electrical appliances, and so on.

XLPE cable has good electrical performance and a large transmission capacity.

Long-term operating temperature up to 90 ° C, instantaneous short-circuit temperature up to 250 ° C.

And lightweight, less production process, fast production, and manufacturing cycle Short, high drop or vertical laying, easy installation and maintenance, and other advantages of the simple structure have been favored by users, more and more popular in the power sector.

Its share in the field of high-voltage, high voltage cables continues to increase gradually replacing the trend of other types of lines.

Currently, the international 220KV and below the voltage level of the main high-voltage XLPE cable insulation, 500KV XLPE insulated cables have also been used in the EHV lines.

The long-term operation and experience show that the aging of the water tree is one of the main factors that lead to the deterioration of the XLPE cable XLPE insulation.

The DL / T 1070-2007 standard defines a water tree as "the presence of moisture in the insulation, Electrical stress, and certain triggers, such as impurities, protrusions, space charges or ions.

When developed into some microchannels. Tubular water trees appear, and bow-tie water trees.

Tubular water trees are formed by the insulation shield or conductor shield.

These water trees start with impurities or other defects in the insulation and progress radially toward the insulation shield and conductor shield.

Water-resistant trees, however, contain cross-linked polyethylene insulation that can retard the development and growth of water-tree insulation, polymer modification, or filler.

Water-resistant tree cross-linked cable is mainly through the semi-conductive material resistance to water molecules penetrating, reducing the depth of water molecules inside the insulation probability.

Improving the molecular stability of insulating materials, and enhancing the water-resistant tree growth characteristics of cross-linked cable materials improves.

In the United States Japan Germany in the late 1980s began to study the waterproof function of medium voltage XLPE cable, so the cable's safety and reliability doubled.

In North America and Europe, water-resistant tree insulation material dominates.

Sophisticated cross-linked polyethylene cables can normally be used for an average of 20-25 years, while water-resistant XLPE cables can Use for more than 40 years.

In recent years, some domestic raw materials and cable manufacturers in the water-resistant cross-linked polyethylene materials, products side Face also have started research work.

To prevent the intrusion of external moisture, UHV cables mainly adopt lead sheath and ultra-clean insulation materials, communication cables

It is mainly the use of aluminum-plastic longitudinal package structure, but for the larger amount of medium voltage power cables, the cost of both methods is too.

Therefore, the most realistic and effective method to restrain the water tree is to create water tree factors such as micro-gaps, impurities, and protrusions.

Specifically, is the use of water-tree insulation materials and clean production technology.