XLPE cable's main insulation material and material is plastic. The performance of thermoplastic is superior, and it has good processing performance, especially for wire and cable insulation layers and protective layers. The basic mode of the plastic insulation layer and the protective layer of the wire and cable is the continuous extrusion of the single screw extruder. Because of the characteristics of continuous extrusion, the production process of plastic insulation and jacket is also continuous.

In terms of the production of XLPE cable, the difference in product specifications, and the difference in the extrusion parts, often determine the change in extrusion equipment and process parameters. But generally speaking, a variety of products, extrusion of various components of the coating process is similar, following a general is given priority to, the individual as a supplement to introduce the type of extrusion principle, process, and die.

The working principle of the extruder is that the specific shape of the screw is rotated in the heating barrel, and the plastic extrusion is brought forward by the hopper, Make the plastic uniform, through the nose and different shapes of the mold, so that the plastic extrusion into the continuity of the various shapes required Plastic layer, packed in the core and cable.

The plastic insulation and sheath of wire and cable are used in continuous extrusion, the extrusion equipment is a single screw extruder.

Before the plastic extrusion goes out, check whether the plastic is wet or free of any other material, and then screw up the screw in the hopper. In the extrusion process, loading in the bucket of plastic with the aid of gravity or feeding into the barrel of the machine, in the rotating screw of the thrust, and continue to move forward, starting from the preheating section a gradual movement of the same segment.

At the same time, the plastic is subjected to the mixing and extrusion of the screw, and the shear between the external heat and the plastic and the equipment of the barrel.

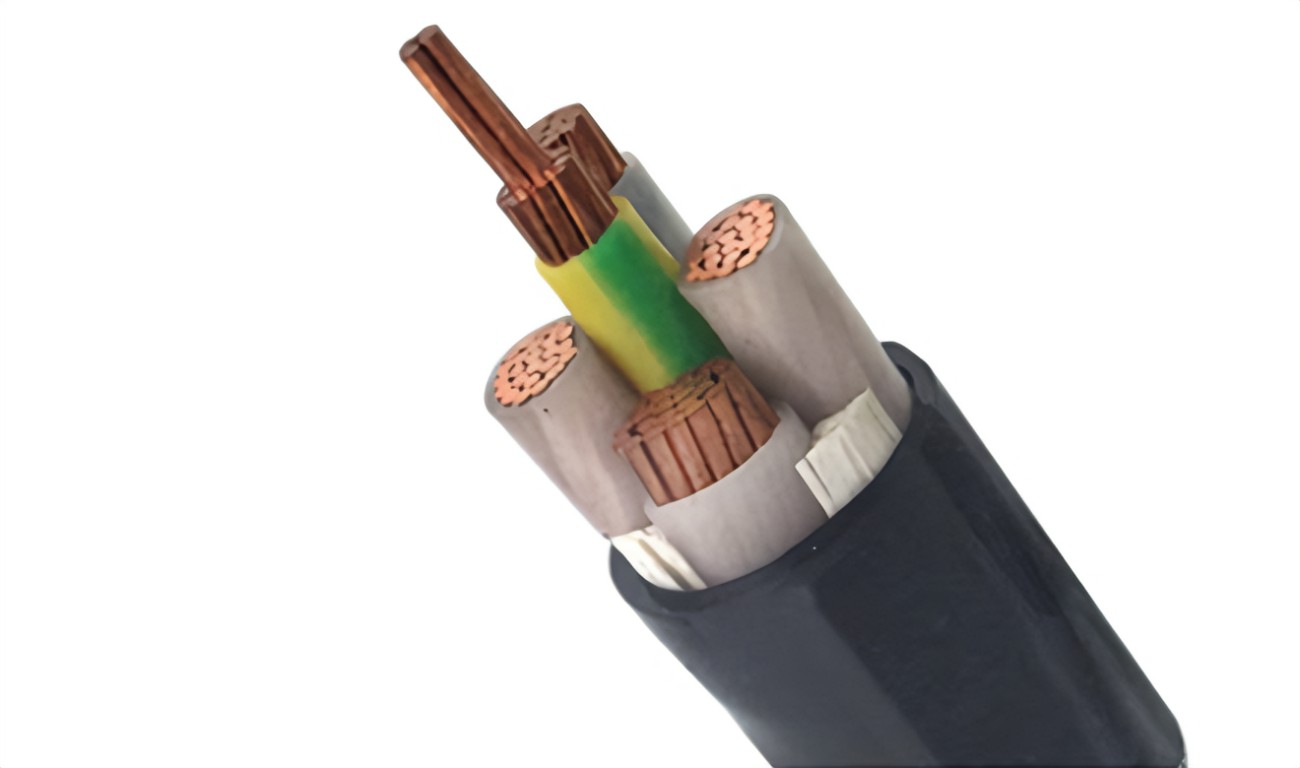

Under the action of friction, the flow pattern is changed into a viscous flow pattern, which is formed in the spiral groove. Under the action of the process, the plastic from the solid state a plastic object, which is transformed into a molten state, is pushed or stirred by the screw, and the plastic is completely plastic pushed into the nose, and the material flow is reached. the mold core and mold suite of the annular gap, is extruded from a die sleeve mouth, extruded to the conductor or wire around the core, insulating layer or sheath layer forming a continuous dense, and then cooled and solidified, made into XLPE cable products.