In general, the ultra-high voltage cable using MDCV process, the conductor section of 800mm2, the use of non-segmented conductor structure, (800mm2 above the use of split conductor structure), the insulating layer nominal thickness of 35.6mm, metal sets of welding flat aluminum sets. Using flame retardant PE material, the design for the snake-like layout.

Metal belt in the horizontal direction and the cable axis parallel to the line, aluminum edge is cut, the surface clean and accurate width, aluminum through a series of plastic mold and cable diameter and the same, the cable from the mold into the aluminum without contact, adjust The aluminum belt is shaped until its edge is close to the cable and has a certain pressure.

The seam is welded with a laser beam, and the weld is inspected by the camera. The welding quality control system detects any defects by means of eddy currents.

After passing through a series of molds Shrink, cable and aluminum tube and then traction through the crawler traction equipment, this track traction equipment, control the entire line speed.

1. Outer jacket and smooth aluminum jacket through a cross head at the same time out.

2. This makes the sheath on the metal shield impossible to wrinkle;

3. This tightly coupled composite aluminum-PE jacket has a bend radius of up to 20 times the cable diameter.

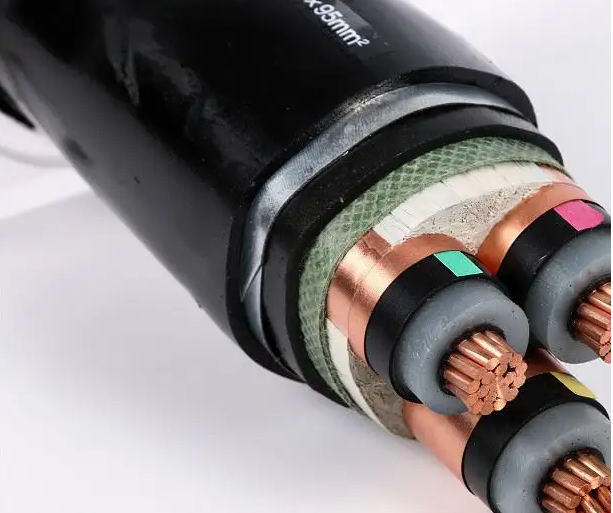

1. copper conductor → conductor shield → insulation → insulation shield → expansion zone → copper wire → anti-bar copper belt → expansion zone → aluminum belt → PE jacket

2. copper conductor → conductor shield → insulation → insulation shield → semi-conductive belt → aluminum belt → PE outer jacket

3. copper conductor → conductor shield → insulation → insulation shield → expansion zone and copper wire shield → expansion zone → aluminum sleeve / (lead) with → PE outer jacket