Aluminum and copper have been proposed for many years, and have been used in Europe and other countries very common, the range of applications is not widespread in Asia, but in recent years many Chinese AAAC conductor companies have begun to try aluminum and copper. General Cable has even and Shanghai Institute of wire and cable standards set out of AAAC conductor.

Because copper compared to aluminum has good electrical conductivity, thermal conductivity, and when the transport current can reduce energy loss, and therefore has been difficult to cut wire and cable manufacturers in regret. At present, in China's wire and cable industry, more than 60 percent are manufactured using copper cables. Because compared to the lack of copper resources, domestic copper resources are proven depth even overexploited.

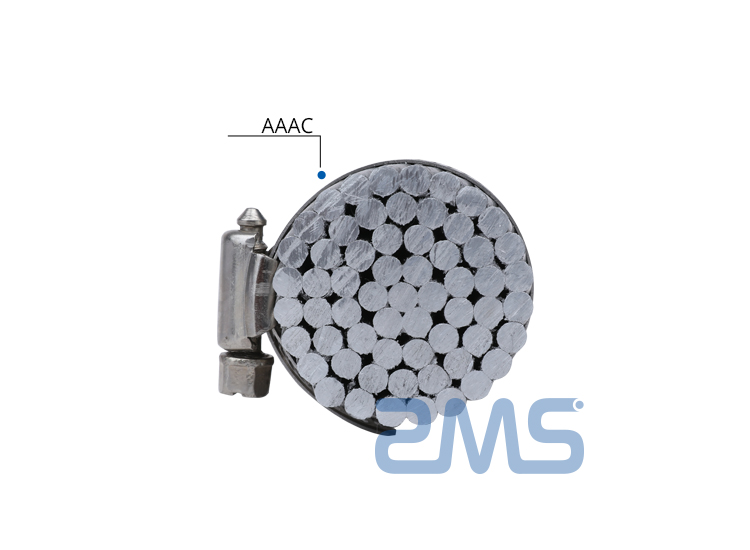

AAAC conductor's electrical properties are comparable with copper cable, its flexibility is better compared to copper cables, AAAC conductor and changes in the past, poor mechanical strength, low resistance to fatigue, joints prone to accidents, and other shortcomings guarantee the continued stability of the cable in case of prolonged overload and overheating of the cable connection, also make up the traditional copper cables memory effect and high rebound properties and other defects, reduce line losses.

In addition, in terms of raw material production, processing, manufacturing, and then transport, installation, operation, recovery, all kinds of ways, AAAC conductor compared to traditional copper cable, have unparalleled economic and environmental advantages cents No doubt that will be the best alternative to copper cable, which is a good thing for heavy and light materials of wire and cable companies, at least to reduce the demand for funds, and to know that China is a very small country's copper production, copper basic imported, but the production of aluminum is indeed a big country. Moreover, aluminum is much lower than copper, reducing demand for funds is undoubtedly very beneficial.

With the haze and other environmental pollution occurring, today there is a growing emphasis on environmental protection, wire and cable industry is no exception, is bound to face environmental requirements. The wire and cable industry mainly refers to environmental protection materials, environmental protection. At present, the production of aaac conductor widely used rubber, polyvinyl chloride, polyethylene, and other polymer chemical materials. A large amount of poisonous gas is in the production process. Therefore, we should actively develop environmentally friendly materials, and produce environmentally friendly aaac conductors.

Fujikura and other cable companies in the development of environmentally friendly aaac conductor, in order to monopolize the market, and actively promote the government enacted environmental protection standard aaac conductor products. In recent years, the share of sales of environmentally friendly rapid expansion of wire and cable, aaac conductor, and ordinary retardant aaac conductor simply can not compete. In addition, the corner generated in the AAAC conductor production process is more than expected, and the recovery can be directly reused.

AAAC cable products more and more there is a tendency to development, namely the development of the cable jacket thinner, smaller cross-section while ensuring ampacity. Compared with the previous several, which require an integrated AAAC conductor industry technology.