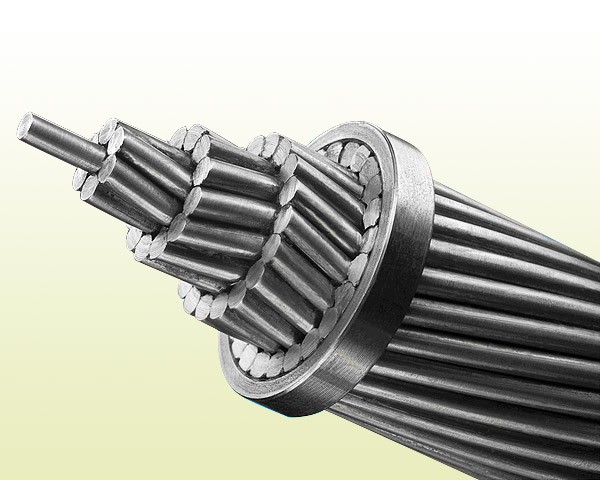

Characteristics of AAAC conductor(in Al-Mg-Si heat-type high-strength aluminum alloy wire, for example), the application surface and development trend of advanced industrial countries in the world, compared with the ACSR AAAC conductor, because of its high strength, lightweight, and good conductivity (53% IACS) and so on.

As early as 1921, it began to be used for overhead lines. With the development of technology to improve power transmission and power transmission lines, the aluminum wire has increasingly shown its superiority, the international community began to use it in the fifties, in Western Europe, Northern Europe, the United States, Canada, Japan, and other countries has been widely used France's transmission line over nearly 90 percent of AAAC conductor, Japan has reached more than 50%, usage surge in Southeast Asian countries in the year (the current application of the amount of less than 1%).

This is because, compared with the AAAC conductor ACSR, has the advantage of its unparalleled decision, in long-distance, large-span, EHV transmission, the exclusive advantage, in the rural power grids, are both advanced and economical a good product, it is the ordinary ACSR replacement products, but also energy, materials, land (save transmission corridor) products and services.

At present, the lack of power transmission capacity problem is very prominent, and the transformation of the transmission line expansion, especially in densely populated areas of economic development, lack of resources in the corridor, met all sorts of resistance.

Recently, the State Grid Corporation of China has made it clear provincial power sector must make full use of existing power corridor resources to develop tolerance to temperature increases in power transmission line technology, use heat-resistant wires, and enhance thermal stability levels for improving transmission capacity of the line. Transmission Line will improve operating temperatures, as an important means of power grids. The state decided to start UHV, for one important reason: that the equivalent of a UHV corridor five EHV line corridor transmission capacity to single-loop design, the unit area of transport corridors of power can be increased to more than three times.

In line narrow area, only need to replace a similar cross-sectional size of the aluminum heat-resistant aaac conductor, basically do not need to replace the tower land acquisition, will be able to meet the increased transmission capacity requirements, so that the original line to improve the transmission capacity of 40% to 60 %, not only saves a lot of engineering investment required rack tower valuable land resources, and rapid construction, resulting in a significant economic and social benefits.

Experts pointed out that, as has long been inadequate investment in power grid construction, power grid construction debts more, cross inter-provincial contact line, big power line and load center send input lines "stranglehold" phenomenon is relatively common, with the relative lack of network power supply capacity, "send not, drop it down, do not have access," the problem to some extent, restricted obvious, actually difficult to meet the growing needs of our people will live in. Resistant aluminum alloy with 60% IACS transmission lines in urban and rural power grids, both saving and environmental protection but also increases the power transmission capacity, is a "green manufacturing" demonstration project, and has great application value.