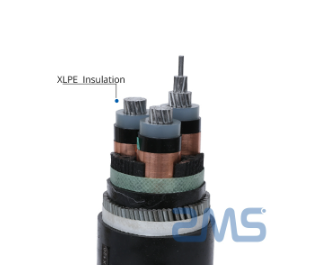

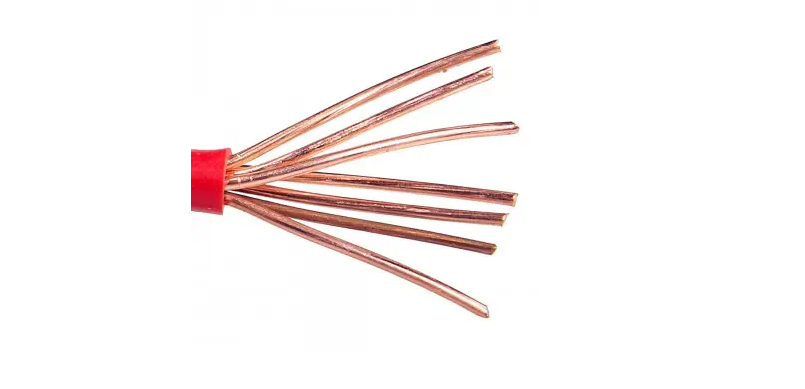

Insulation material is the basic mechanism of additive react with copper conductors, produce copper compounds, with continuous reaction, copper will change color black, corrosion, resistance increase.

This phenomenon is the quality problem of the cable companies often face, and this color is often happen in the end user, will cause greater economic and reputation losses.

In 2012, one well-known domestic cable manufacturing company for product steam bath after crosslinking copper conductor oxidation discoloration, lead to export more than ten dish cable scrap return。

Not only caused huge losses to the enterprise, also lost very not easy to get foreign markets.

To the problem of copper conductor oxidation caused by many factors, such as copper conductor, boiled water or steam crosslinking time problem, and material issues.

Copper conductor will increase the rate of conductor resistance after oxidation discoloration, which not only affect the product appearance, also affect the quality of the product.

To solve the above problem, in addition to choose the oxidation resistance of copper conductors.