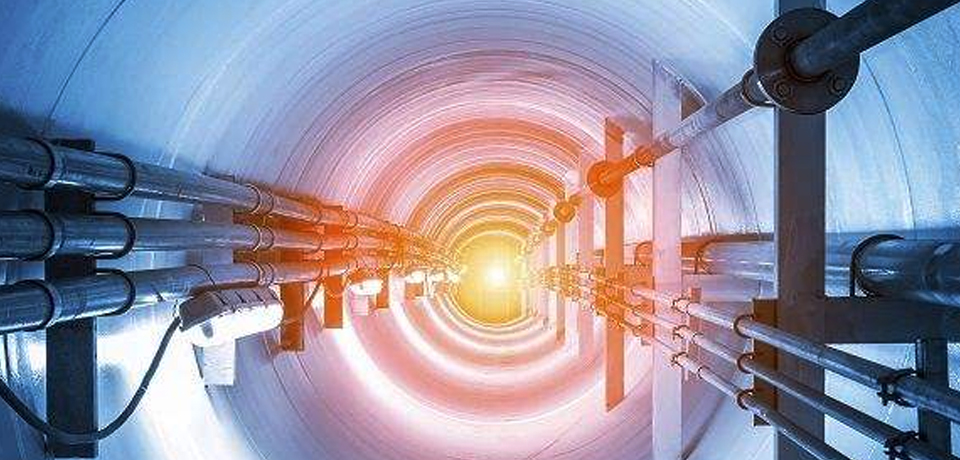

Medium and low voltage cable laying is about the appropriate number of cables laying a certain technology to establish a safe, reasonable and effective power system. In the process of laying medium voltage power cable.

We must first ensure the quality and integrity of the medium voltage power cable to prevent the cables from being damaged during transportation or under external force, and to ensure the cable laying with high quality Effectiveness; Secondly, as much as possible to reduce the cable cable and bracket, ground and other parts of the degree of Ma rub to avoid excessive damage to the cable performance.

Medium voltage power cable installation mainly includes the installation of cable terminal accessories and cable connector installation. Medium voltage power cable terminal accessories and intermediate connector installation is the weakest link in the construction process of medium voltage power cables. The installation quality will directly affect the safe operation of the entire distribution system. According to incomplete statistics, line faults caused by poor installation quality account for more than 80% of the total line faults. In this regard, in the construction of medium voltage power cables should be given sufficient attention to ensure high quality to complete the installation of medium voltage power cables.

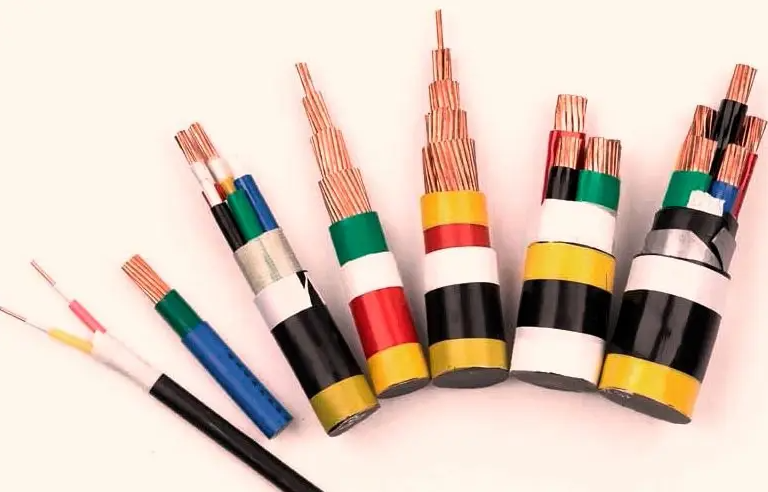

Medium voltage power cable terminal accessories can usually be divided into shrink cable accessories and shrink cable accessories two. According to the characteristics of cable materials, user requirements and the current construction conditions, it is recommended to choose shrink cable accessories, although the higher the price, but the safety is also higher.

Medium voltage power cable terminal accessories installation process is: Stripping the outer sheath of the cable → Remove the steel tape armor layer (optional, if at the same time check the single core cable armor material is non-magnetic metal tape) → Stripping cable Isolation sleeve (optional) → Welded copper strip shield ground wire (good core marking line) → Remove the insulation shield (10KV cable insulation semi-conductive shield is generally peelable type, easy to peel off; 35KV cable insulation semi-conductive .

The shield is not peelable type, special care should be taken not to damage the insulation treatment) → clean the insulation surface → install the semiconductive tube → install the branch gloves → stripping the insulation layer and the conductor shield (cut into pencil head shape) → install the insulation sleeve Tube and terminal. In the installation of medium voltage power cable terminal accessories should pay attention to the following aspects:

Copper grounding wire should be welded firmly; stripping conductor shield, do not damage the conductor, causing burrs, causing the cable partial discharge exceeded; terminals should be matched with the cable conductor material, the aluminum conductor should be used excellent quality copper and aluminum Transition terminal, and the terminal filled with conductive paste, crimping terminal from the beginning, and crimping in place; cable insulation and terminal contact surface should be handled perfectly to ensure that the seal intact, otherwise it will have a lot of trouble spots.