Wire and cable in the power system, especially in the transmission line is essential, there are several kinds of classification, there are special cables, insulated cables and so on, the following will be the most comprehensive introduction!

(1) The temperature reflects the ultra-high, or the control temperature of the instrument failure, resulting in ultra-high temperature and coke burning plastic.

(2) The nose of the mouth of the gum is large, there is a strong smell of stimulation, and also crackle.

(3) The plastic surface appears granular coke burning.

(4) There are continuous pores at the joint.

(1) High temperature control results in the burning of plastics.

(2) Screw rod long-term use without cleaning, coke burning material accumulation, with plastic extrusion.

(3) Heating time is too long, plastic accumulation of long-term heating, so that plastic aging and scorched.

(4) The parking time is too long, without cleaning the head and screw, causing the plastic decomposition Coke burning.

(5) Many times to change the mode or color, resulting in the decomposition of coke burning plastic.

(6) The head gland is not pressed tightly, and the plastic is decomposed in the inside.

(7) Control temperature of the instrument failure, resulting in ultra-high temperature after burning.

(1) Regular check whether the heating system is normal.

(2) Regular cleaning screw or nose, to thoroughly clean.

(3) According to the requirements of the process heating, heating time should not be too long, if the heating system has problems to find the relevant personnel to solve.

(4) To change the mold or color to be timely, clean, to prevent noise or storage coke burning.

(5) Adjust the die after the mold sleeve to press tight, to prevent the glue.

(6) found that burnt burning should immediately clean the nose and screw.

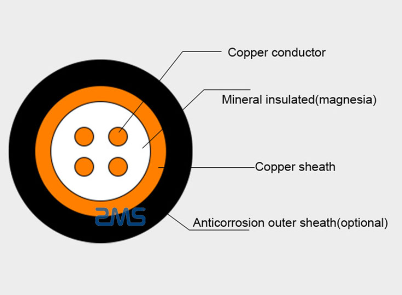

The inside of the copper wire is copper high-temperature processing!